BOLOGNA, Italy – The new ACMA machine for multi-style packaging of 600 chocolates per minute will be displayed at ProSweets exhibition. ACMA, a company of the Coesia Group, will display a new mid-speed multistyle machine for the packaging of chocolates and candies at the ProSweets exhibition of Cologne.

With the distinguishing feature of a compact layout, this machine is directed to realities of the confectionery sector that are looking for flexible and technologically advanced solutions – also thanks to the high wrapping quality with double product centering – at the same time providing an excellent price-quality value.

This new machine completes the wide portfolio of ACMA solutions for the confectionery industry.

The response to market demands

ACMA has a long tradition of design, manufacture and commercialization of automatic machines for large consumption goods, being able to boast of a unique worldwide technological know-how for confectionery products.

During the Cologne exhibition, from January, 31st to February, 3rd, the Italian company member of the Coesia Group, will display for the very first time an automatic alternating movement machine designed for the packaging of chocolates, candies and toffees with flat base.

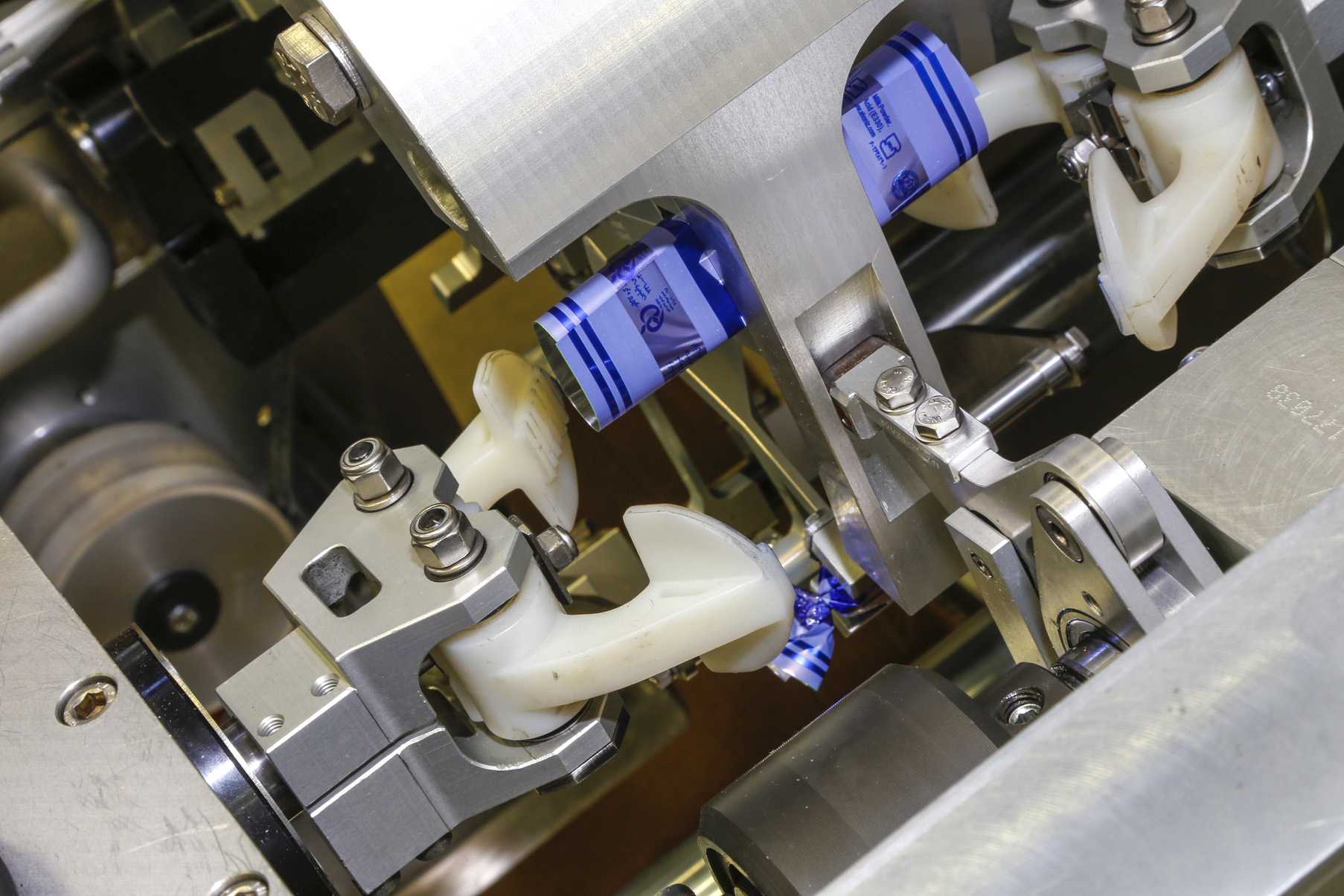

It is a particularly attractive solution for the global market, since it combines a compact layout – that permits perfect integration in various production environments – with the possibility of obtaining various styles such as bunch, double twist, boero, portafoglio and “fancy” ones, while at the same time guaranteeing vey gentle product handling.

The flexibility of the ACMA solution is further enhanced by the possibility of independent reel unwinding, which guarantees perfect packaging also in the case of products with inner and outer wraps having different dimensions. With respect to this, it is to be mentioned that this packer can handle all the main types of wrapping material, from alufoil to plastic compounds.

The new machine is the result of accurate engineering studies. Its construction is modern and ergonomic so that it facilitates maintenance and cleaning operations, as it is easily accessible as well as extremely sturdy and reliable thanks to the brushless motors.

Power consumption levels are particularly low. As all the latest generation ACMA solutions the machine is equipped with the ARA (Advanced Remote Assistance) system, a tool for the remote control of the machine functions by specialized Acma technicians through a simple LAN connection.

M888: multi-style even at high speed

This machine, that will be on display in Cologne, is part of the wide portfolio of solutions for the confectionery industry, which includes machines for the most widely varying necessities.

As part of the multi-style solutions, the Italian company can offer M888, a high-speed unit, which has met with considerable approval from the market.

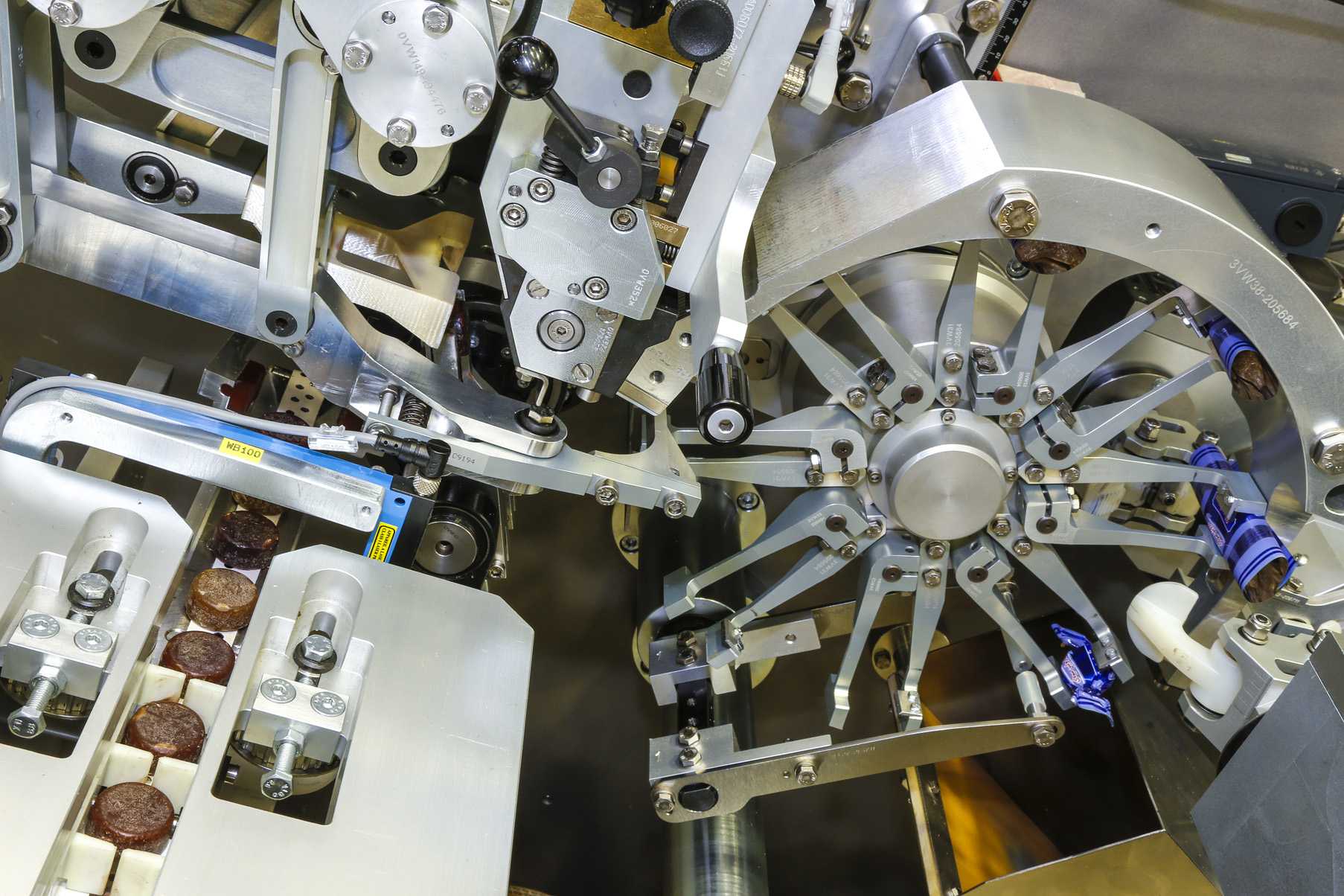

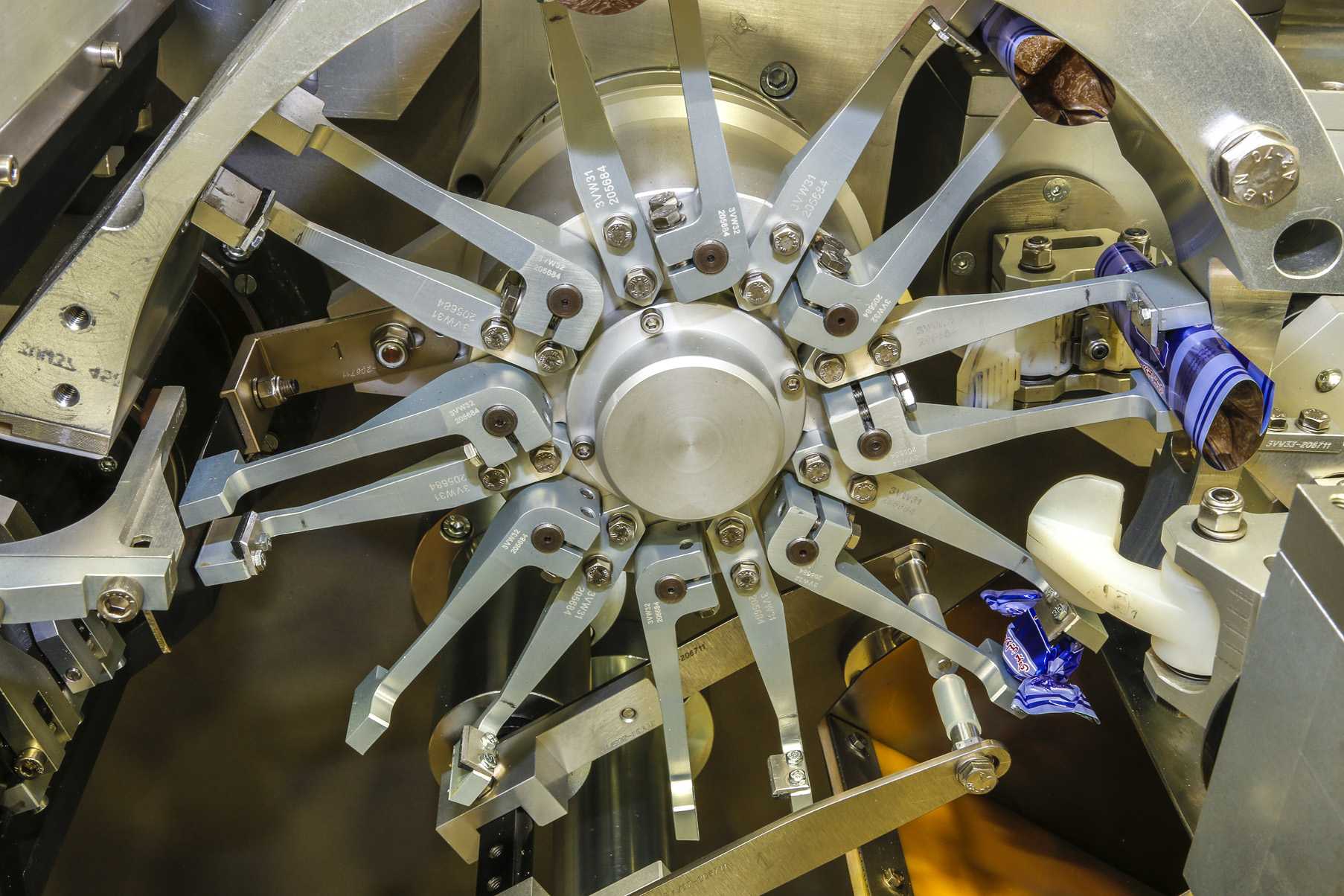

This machine, as well as the mid-speed version, is suitable for the packaging of a wide variety of products – including candies, toffees and chocolates with different forms and dimensions – and is designed to guarantee the utmost care during the handling of very delicate products in the various wrapping phases.

M888 comvines the advantages of the continuous infeed – namely higher speed and greater delicacy when handling “naked” products during the first packaging phases – with the benefits of alternating movement, so as to guarantee higher precision during the wrapping process.

The ACMA machine also permits very quick sizegroup changeover. This operation involves the replacement of a very limited number of mechanical components and requires an average of sixty minutes, depending on the product type.

The flexibility of the M888 permits obtaining various wrapping styles; fancy, portfolio, double twist, Vienna and bon bon.

“SP” series, the ideal flowpackers for the confectionery sector

As concerns the flowpacking technology, ACMA offers three different types of packers: SP0, SP1 and SP2, dedicated to confectionery and bakery sectors.

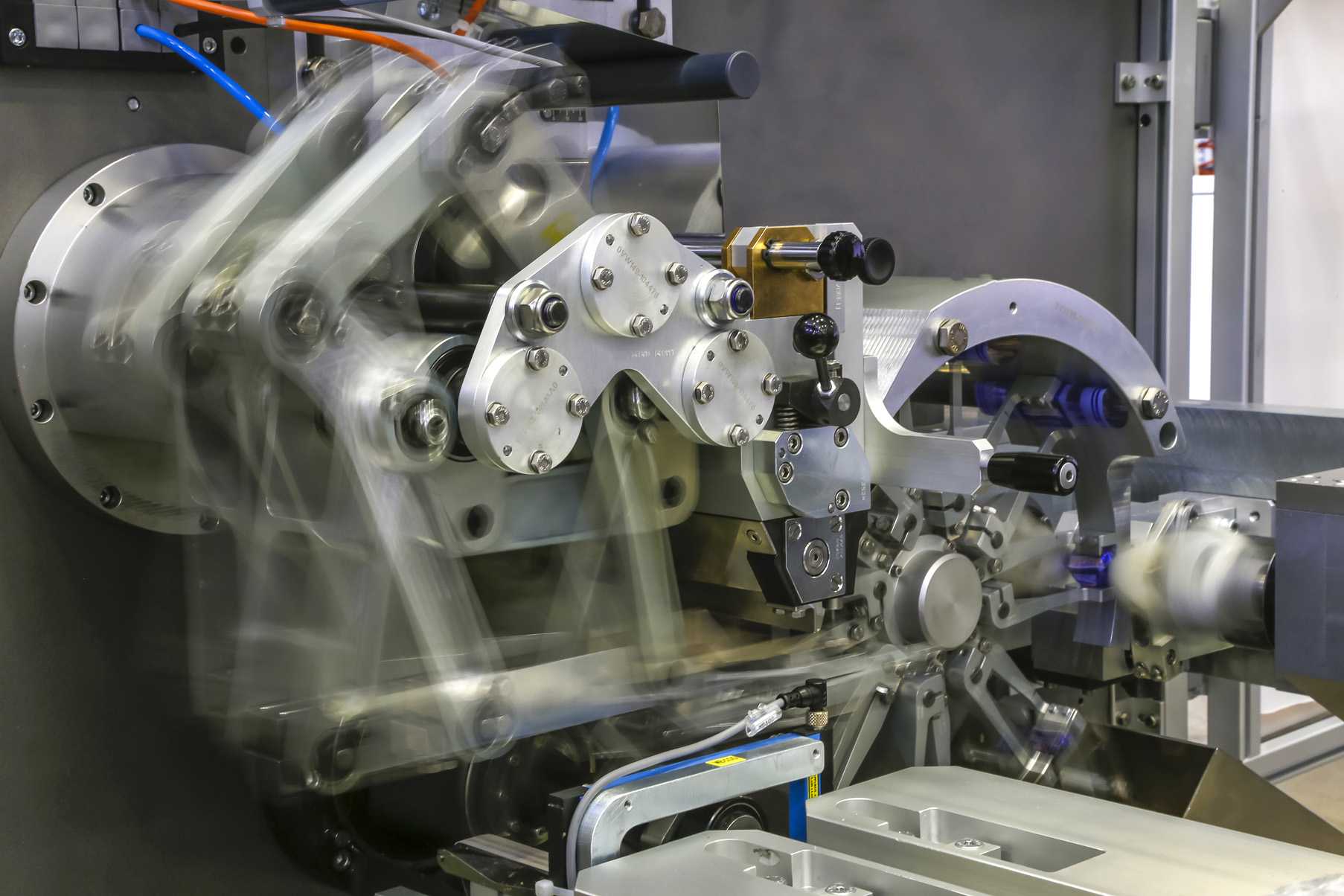

The SP series flowpacker permit mid and high speed packaging of individual or multipack products, with cold or hot sealing The widthwise rotative group can also be supplied in the “long-dwell” version, which, thanks to its translation movement during sealing, permits the high-speed handling of especially resistant materials in order to ensure the utmost air-tightness of the packaging.

The wrapping film unwinding system is equipped with an automatic splicing group that permits quick reel replacement, without having to stop the machine. For the top-range version (SP2, capable of reaching a speed of 120 meters of film per minute) an ACMA patented device for pneumatic film stretching guarantees maximum performance levels and at the same time interrupts unwinding in case of product absence.

ACMA and FlexLink: synergies for the confectionery sector

ProSweets will also offer the opportunity of showing the synergy between ACMA and FlexLink, the Swedish company of the Coesia group.

The multinational group, with a solid and wide-ranging know how, supports the technologic synergies of its companies in the development of integration projects for production lines directed to the relative reference markets.

Most specifically, the unit on display in Cologne will be equipped with an U-shaped conveyor manufactured by FlexLink: this system is already known and appreciated by the market, and will be configured according to the specs provided by ACMA.

This conveyor will become an integral part of the ACMA packer and will enable the made in Italy host machine to handle the products optimally, guaranteeing a constant flow and accurate handling, contributing to attaining high production performance levels.