ACMA, a company of the Coesia Group, offers a complete range of Confectionery products with solutions that meet the high qualitative needs and standards required by the market.

In Cologne, the company will showcase high- and low-speed sweets and chocolate wrapping machines.

Working together to grow

ACMA – historic Confectionery leading brand belonging to the Coesia Group – produces automatic packaging machines in this field, selling them with its brand exclusively. For more than ninety years, this brand has been a guarantee of quality, attention to aesthetics and innovation, in Italy and abroad.

In Cologne, ACMA will showcase a broad range of Confectionery products, by displaying three sweets and chocolate packaging machines for flat base and double twist format products.

The wide range of solutions offered is a tangible expression of the technical cooperation with XPack, Coesia associate company, and with the other companies within the Coesia group. EMMECI, another company belonging to the Coesia Group, will also be present at the stand, with its expertise on high-end chocolate packages and boxes.

For ACMA and its partners, the Cologne trade fair will be an important occasion to share their technological skills and their wide range of solutions.

HW 900 and CW 1000 F-M

One of the machines showcased will be the new HW 900 fold wrapper for high-speed packaging of double twist sweets, which follows the footsteps of the 1100 machine. HW 900 boasts top performance (with a packaging speed of up to 900 pieces/minute) and renewed design, and technical features, which increase its efficiency and productivity.

This machine is more compact, thanks to the new aluminium base; its increased sturdiness and its new mechanical design reduce stress and wear and increase acoustic comfort.

The “cantilever” structure of the mechanical groups and the adjustments in front ensure full accessibility to facilitate maintenance and management operations and to improve the operator’s safety. Furthermore, given the reduced quantity of format components, changes can be made quickly. The vertical paper-unwinding plane allows employing a wide range of wrapping materials, including high-quality and low-cost products.

HW 900 is equipped with latest generation electronics and with the Advanced Remote Assistance (ARA) system that provides remote support by ACMA qualified personnel through a simple network connection.

These features rightfully place the HW 900 in the Industry 4.0 scenario that the Group has been tackling for quite some time with an innovative digitalization process. Product care and attentiveness – a distinguishing mark of ACMA solutions – have remained unchanged, ensuring extraordinary quality.

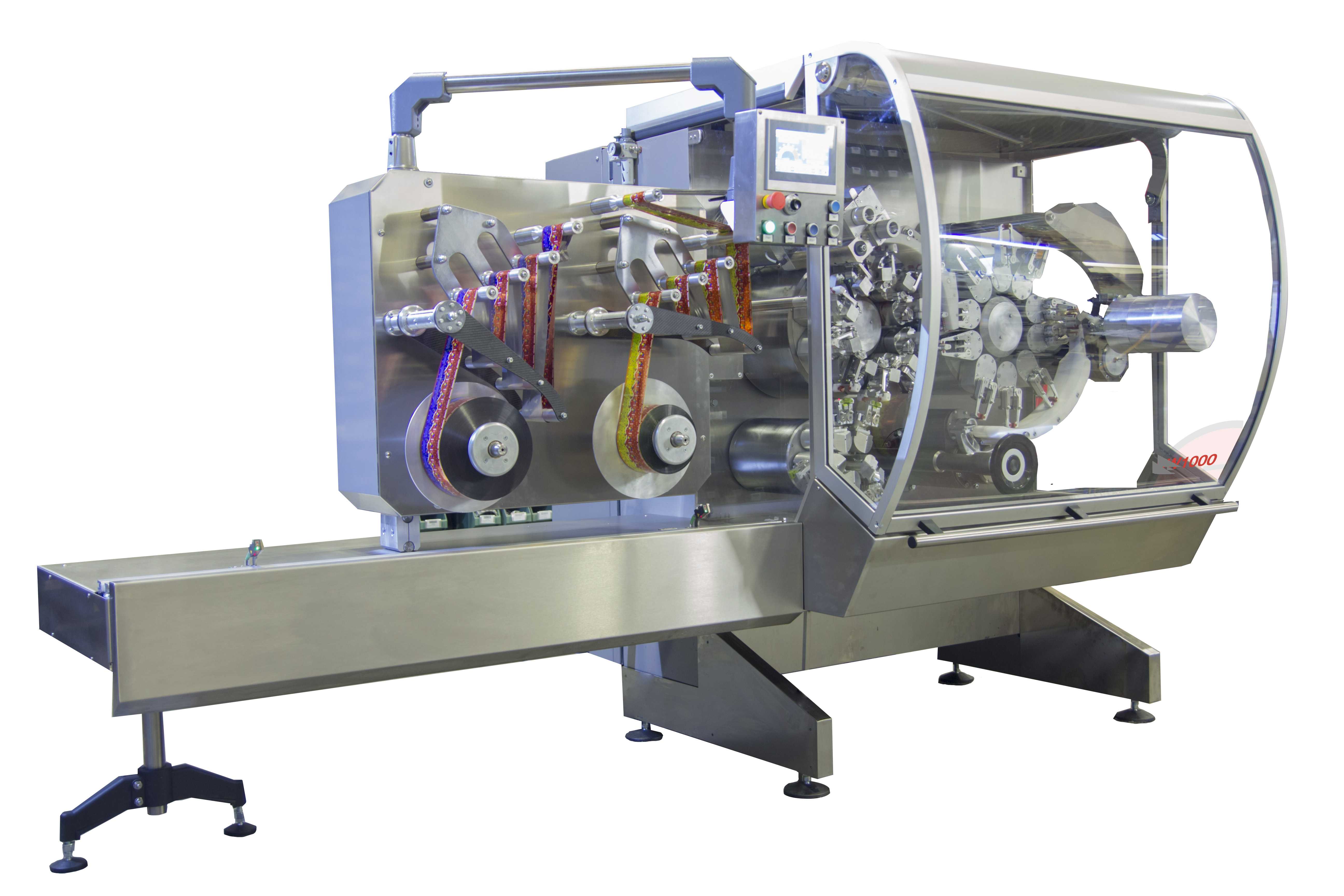

A second machine to be showcased will be the CW 1000 F-M, a continuous movement multi-style chocolate machine, which offers high flexibility and performances up to 1000 ppm. This machine – designed by XPack exclusively for ACMA – has been designed for flat base products and it manages the wrapping formats in demand on the market.

Apart from its high performance, the new CW 1000 F-M features a compact design, thanks to the mobile splicing timing system. Its continuous motion architecture ensures a delicate product processing and higher folding times to obtain a perfect wrapping quality. The machine reliability and sturdiness are ensured by its completely mechanical structure.

These two machines complement the existing ACMA Confectionery range, which includes the CW 600 and the CW 850 F-M for flat-base chocolates, the CW 800 R and the CW 1000 R for round chocolates, and the GS 1000 and HS 1000 for sweets in stick packs. The range also includes high-performing flow packing solutions, such as the CF 1000 and CF 1200 machines.

XPACK focus

XPack, a company founded in 2011 by Mario Spatafora, develops highly technological wrapping machines mainly for the Confectionery field. The solutions offered by XPack meet the diverse market production and financial needs, by combining flexibility and quality product management.

Apart from chocolate wrapping machines, XPack has created single projects for the soap and coffee field over the years, highlighting the company’s technical versatility. XPack core business portfolio includes:

Miniwrap – manually loaded wrapper with variable 100-130 ppm speed, depending on the operator, which can pack chocolates with over 10mm of clearance between one another. Ideal for the artisanal sector, its flexibility ensures management of the main wrapping formats on the market: bunch, wallet, napolitain, double and single twist. Format changing takes 1h and, optionally, it can be equipped with a labeller and with magazine loaded clamps.

Flexiwrap – medium speed (up to 350 ppm) multi-style wrapper that allows to obtain several wrapping formats with a single product with a style / format change that takes 1 hour. The wrapping groups are arranged on the same base to prevent cam change.

Strengthened by more than twenty years of experience of its founder, XPack is a dynamic reality focused on market trends and capable of offering custom solutions depending on its customers’ size and business, by offering a range of valid solutions for every market sector.

EMMECI focus

Emmeci has a long tradition in the development and production of machines to manufacture rigid cardboard boxes for the luxury segment. During the Prosweets Cologne 2018 exhibition, Emmeci will be at the visitors’ disposal to give information about its portfolio of automatic solutions for the production of high-quality rigid cardboard boxes and to show the high-end products these machines can realise.

Emmeci offer actually includes the state-of-the-art of technology for the production of ‘premium packaging’ for different sectors of the market: accessories/fashion, cosmetics and perfumery; chocolate and confectionery; wines and liquors; sparkling wines and champagne; electronics and multimedia; jewellery and watches; pharmaceutical; crystal ware and home accessories; games.

ProSweets, Cologne (Germany)

January 28th – 31st 2018

Hall 10.1, Booth G48 H49