BOLOGNA, Italy – IMA Group, a world-leading designer and manufacturer of automatic equipment able to reach every corner of the coffee processing and packaging universe, will show at Host 2019 five machines from companies composing the Coffee Hub.

IMA has recently established the Coffee Hub, a cluster of specialist brands, each providing a key slice of the experience and expertise needed to serve the coffee industry from A to Z.

Able to ensure market-leading competences, industry experience and application-specific know-how encompassing all stages of coffee handling, processing and packaging, IMA has created the hub in an aim to leverage expertise at every step of coffee processing or packaging and be the one-stop answer to large and small coffee producers worldwide.

IMA Coffee Hub reaches every corner of the coffee handling, processing and packaging universe.

Comprising a handful of expert companies and supported through consolidated, strategic partnerships, IMA can now address any issue facing coffee producers, starting from when green coffee is delivered to when bulk-packaged capsules, pods and ground coffee or beans are shipped to retail outlets.

On show on IMA booth, Hall 22 – Booth #L16-L26 M15-M25, the best coffee processing and packaging solutions.

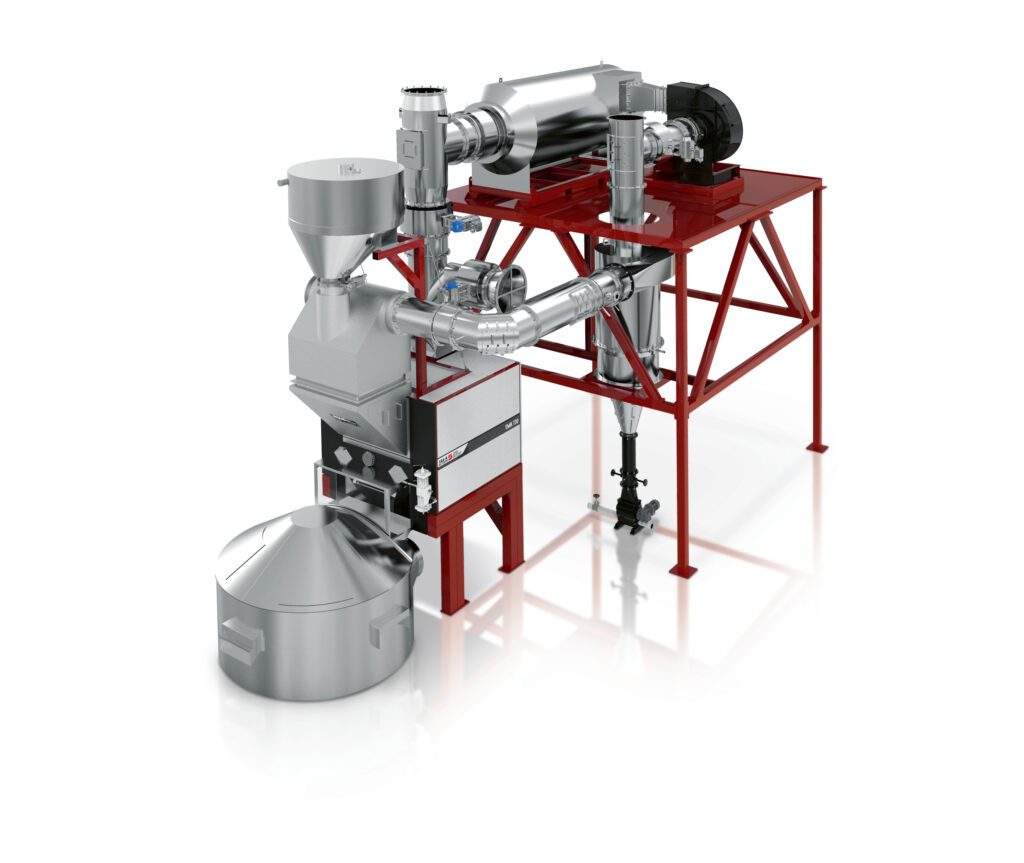

Petroncini TMR400

Drum roaster

Through its Petroncini brand, IMA provides expert consultancy and a complete range of equipment for green and roasted coffee handling and processing, roasters for all capacity requirements and high-quality grinders. The Petrocnini TMR400 roaster has been specifically designed for industrial productions that require high profitability and repeatability of the roasting processes throughout the various working stages. A dedicated software allows to maintain a consistent product quality right from the first batch, when the machine is cold, up to the last roasting cycle.

Through its Petroncini brand, IMA provides expert consultancy and a complete range of equipment for green and roasted coffee handling and processing, roasters for all capacity requirements and high-quality grinders. The Petrocnini TMR400 roaster has been specifically designed for industrial productions that require high profitability and repeatability of the roasting processes throughout the various working stages. A dedicated software allows to maintain a consistent product quality right from the first batch, when the machine is cold, up to the last roasting cycle.

The roasting curves are previously designed by setting the time and bean temperature as independent variables. The control system follows exactly the setting parameters in order to reach the roasting time, color, moisture and taste desired. That’s why the system is suitable for frequent recipe changes and non-traditional profiles whilst guaranteeing repeatability.

Spreafico SR6N

Aluminum capsules filling and sealing machine

Spreafico Automation, part of IMA Coffee Hub, will show at the Milan event a six-lane machine for the filling and packaging of Nespresso® compatible aluminum capsules. Being one of the most common capsule styles on the market, it guarantees both a top quality final product as well as its recyclability, as the capsule is completely free from plastic laminates. Based on the afore mentioned features, that have made its success, the aluminum capsule requires dedicated packaging machines, guaranteeing a particularly gentle process, starting from the feeding phase up to filling and sealing.

Spreafico Automation, part of IMA Coffee Hub, will show at the Milan event a six-lane machine for the filling and packaging of Nespresso® compatible aluminum capsules. Being one of the most common capsule styles on the market, it guarantees both a top quality final product as well as its recyclability, as the capsule is completely free from plastic laminates. Based on the afore mentioned features, that have made its success, the aluminum capsule requires dedicated packaging machines, guaranteeing a particularly gentle process, starting from the feeding phase up to filling and sealing.

Spreafico Automation boasts a unique know-how in this specific segment being also supported by the experience gained in IMA Coffee GIMA where applications for compatible aluminum capsules have been developed on high-speed machines. The SR6N is perfectly tailored to the market needs – medium-high production speed (up to 360 capsules per minute) encompassing at the same time all the Spreafico’s well known technological features guaranteeing great reliability and top quality product.

Mapster MCA2

Capsules filling and sealing machine

IMA Coffee Mapster designs and manufactures entry level capsules packaging machines running at medium-low speed. Thanks to technically advanced solutions, competitive prices and proven reliability, Mapster represents a reference in the market.

IMA Coffee Mapster designs and manufactures entry level capsules packaging machines running at medium-low speed. Thanks to technically advanced solutions, competitive prices and proven reliability, Mapster represents a reference in the market.

The MCA2 capsules filler is a machine dedicated to those who do not want to accept any quality compromise despite having limited production needs. Thanks to the synergy with IMA, the machine shows several technical improvements that guarantee its high quality standards. The MCA2 is a 2-lane machine with handling chain, input pick & place with heads and cutting and welding device for filter (bottom lid and/or top lid) in a unique station.

Gima FTB584-C

Capsules cartoning machine

IMA Coffee Gima occupies a leading position in the global coffee market and it covers all aspects of the packaging process, from consultancy and design to production planning and turnkey solutions: provides pods and capsules packaging machines and cartoners.

IMA Coffee Gima occupies a leading position in the global coffee market and it covers all aspects of the packaging process, from consultancy and design to production planning and turnkey solutions: provides pods and capsules packaging machines and cartoners.

The FTB584-C is designed to run in line with the IMA Coffee filling machines.

The experience IMA has in conceiving specially tailored solutions makes it the ideal strategic partner for industry leaders who constantly strive to satisfy new market trends.

As a turnkey solution, the FTB584-C offers countless plus points: compact footprint, user-friendly operator interface, high blanks capacity, quick size changeover and requires minimal maintenance. With fully servo-driven movement, the FTB584-C ensures excellent production efficiency and extreme flexibility regarding the product layer configuration. A key feature regards the minimal use of void space, enabling highly compact packaging solutions to save space and cut costs.

Tecmar 3C-130

VFFS bags packaging machine

Part of the Hub and with 25 years of specific experience, vertical form-fill-seal expert Tecmar provides machines handling dosed filling of flexible, sealed packages in all shapes and sizes.

Part of the Hub and with 25 years of specific experience, vertical form-fill-seal expert Tecmar provides machines handling dosed filling of flexible, sealed packages in all shapes and sizes.

The 3SS bagger model 3C-130 guarantees a high performance output in the packaging of ground coffee and beans.

The design of this machine is based on an Open Frame architecture that provides easy cleaning and accessibility for maintenance and operational adjustments.

The machine is controlled by a PLC and equipped with a user friendly 10” HMI, a motorized film unwinding unit, a pneumatic film tension controller and a motorized film alignment system.

The machine is controlled by a PLC and equipped with a user friendly 10” HMI, a motorized film unwinding unit, a pneumatic film tension controller and a motorized film alignment system.

The machine on show at Host is customized to produce Quad seals (Stabilo) bags including degassing valve applicator and N2 flushing system.