COLUMBUS, Ohio, U.S. – For over 28 years, Crimson Cup Coffee & Tea has hand-roasted award-winning coffee in small batches. Roast Master Dave Rochus and his team carefully monitor factors such as temperature, aroma, moisture content, color and sound of the coffee beans to achieve a consistent roast.

Rapid growth at the Columbus coffee company prompted a search for a new roaster that would deliver the same consistency on a larger scale. The coffee team settled on a Probat R-23 drum roaster customized to Crimson Cup‘s specifications.

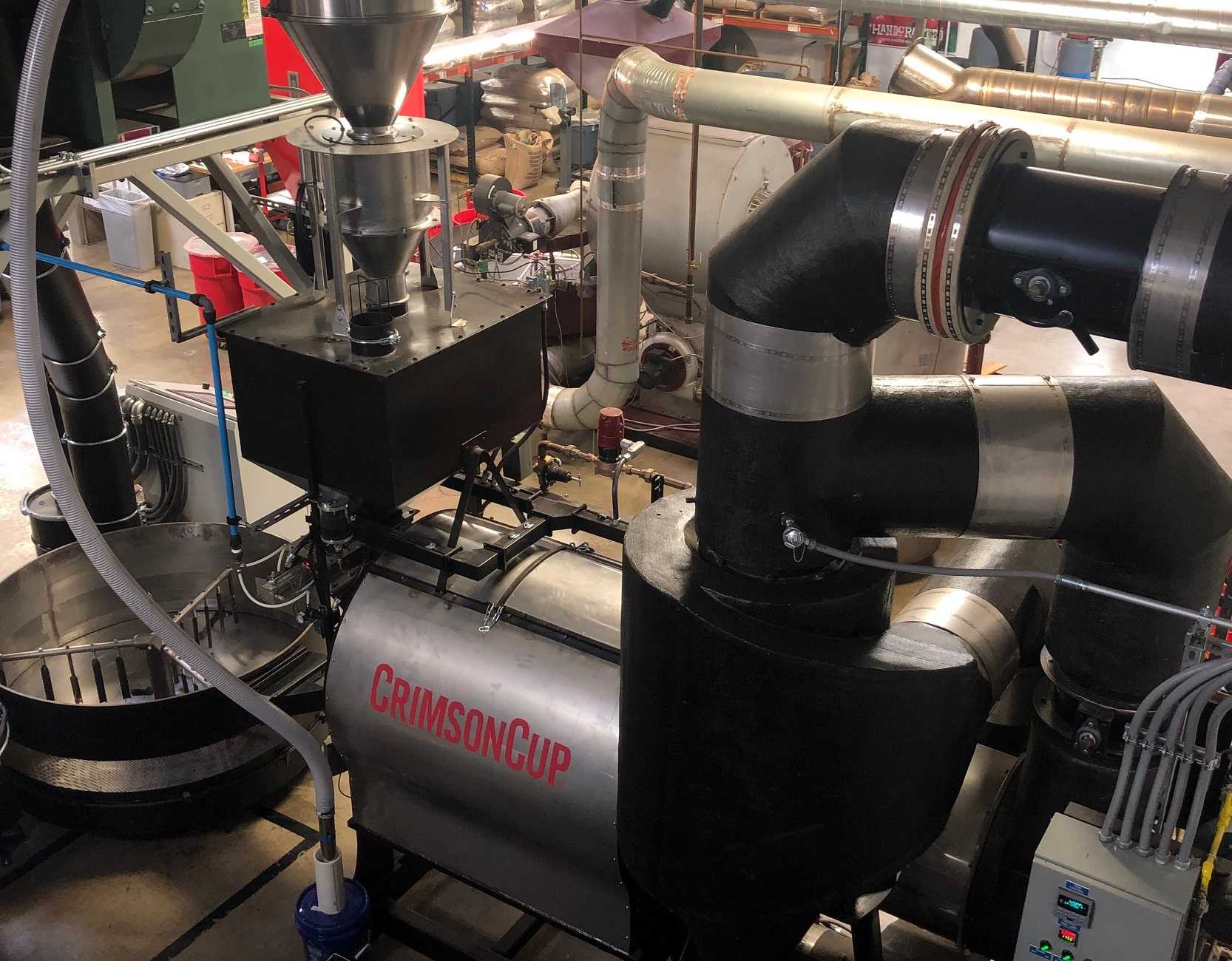

The new machine, The Kracken, now presides over the company’s 20-000-square-foot roasting facility on the east side of Columbus. The four-bag roaster can produce 500 pounds of coffee per batch – all under careful monitoring by Rochus and his team.

“We’ve had a pair of 25-pound Probat roasters nicknamed Hansel and Gretel for over 20 years, so we were sold on the quality,” said Founder and President Greg Ubert. “New computer controls with the R-23 allow us to deliver small-batch consistency with larger roasts.”

Rochus pointed to Probat‘s on-line control systems, which allow his team to monitor and control the roast. “Moving a roast recipe from a smaller to a larger roaster – and vice versa – can present a challenge,” Rochus said. “We’ve found that the Probat process control system allows us to handle this with ease.”

He noted that the Reflection Control Module allows automatic reproduction of product temperature curves after they have been initially defined, while the Colorette tool assists with color measurement. The roasting team also continually measures coffee density using a small sample from each batch.

Operations Manager Joe Blankenship said the new roaster will assist with quality control and efficiency as the roaster delivers over 600,000 pounds of coffee in 2019 to a network of coffee shops, specialty grocers, colleges and universities and food service operations across 37 states, Guam and Bangladesh.

“Life is better in the production facility because of it,” he said.