iCapsulate is a contract manufacturer based in Sydney, Australia, a vertically integrated company specializing in Coffee. iCapsulate sources green coffee, roasts coffee and produces capsules, pods and roasted coffee beans.

iCapsulate is the largest single serve manufacturer in the Southern Hemisphere with a capacity of 1.3 million capsules soon to increase to 2 million capsules per day and roasting capacity of 10 tonnes per day. iCapsulate is constantly innovating and bringing new products to market.

The reasons for choosing CAMA Group

Kane Bodiam, iCapsulate Managing Director, explains why Cama was his choice. “When selecting our secondary packaging machinery there were many options, but when we drilled down to the requirement and flexibility we wanted, only Cama ticked the boxes. Cama offered a machine with exceptionally build quality; the flexibility with the machine and ease to change and adapt formats at minimal cost is a huge benefit, especially for a business who is contract manufacturing. We found the interface to be very user-friendly, servicing is basic and inexpensive for a machine of such quality. There is no need to keep extensive parts, while the consumable parts that need replacement last quite long and are very durable anyway.”

“The local support in Australia is fantastic and I have found them very responsive: considering the short notice I have given, I have always had the technical intervention when I required.”

Cama have exceeded my expectations, and without their support we would not be as successful as we are today.”

Cama Australia Pty Ltd. is the Australian Subsidiary of Cama Group, an Italian private company based near Milan, whose core business is the engineering and production of complete high technology secondary packaging systems and machines.

Its outstanding packaging knowledge combined with a unique machine range (Packaging Division) and robotic loading units (Robotic Division), highlights Cama Groups capability to offer completely integrated packaging lines from primary packages all the way through to final packaging ready for palletizing.

Cama was established in 1981 and has been designing and manufacturing its own robotic systems for over 30 years, working across Food, Dairy, Coffee, Tea, Chocolate, Biscuit, Ice cream, Pet Food and Non Food industries.

The group invests 5% of its yearly turnover in research and development, devoted to continual upgrading and technical development of machines and packaging systems with the purpose of increasing and maintaining a high quality technology in several market fields. The Cama Packaging Dept. also offers its long experience and know-how in cardboard packaging design and customer support.

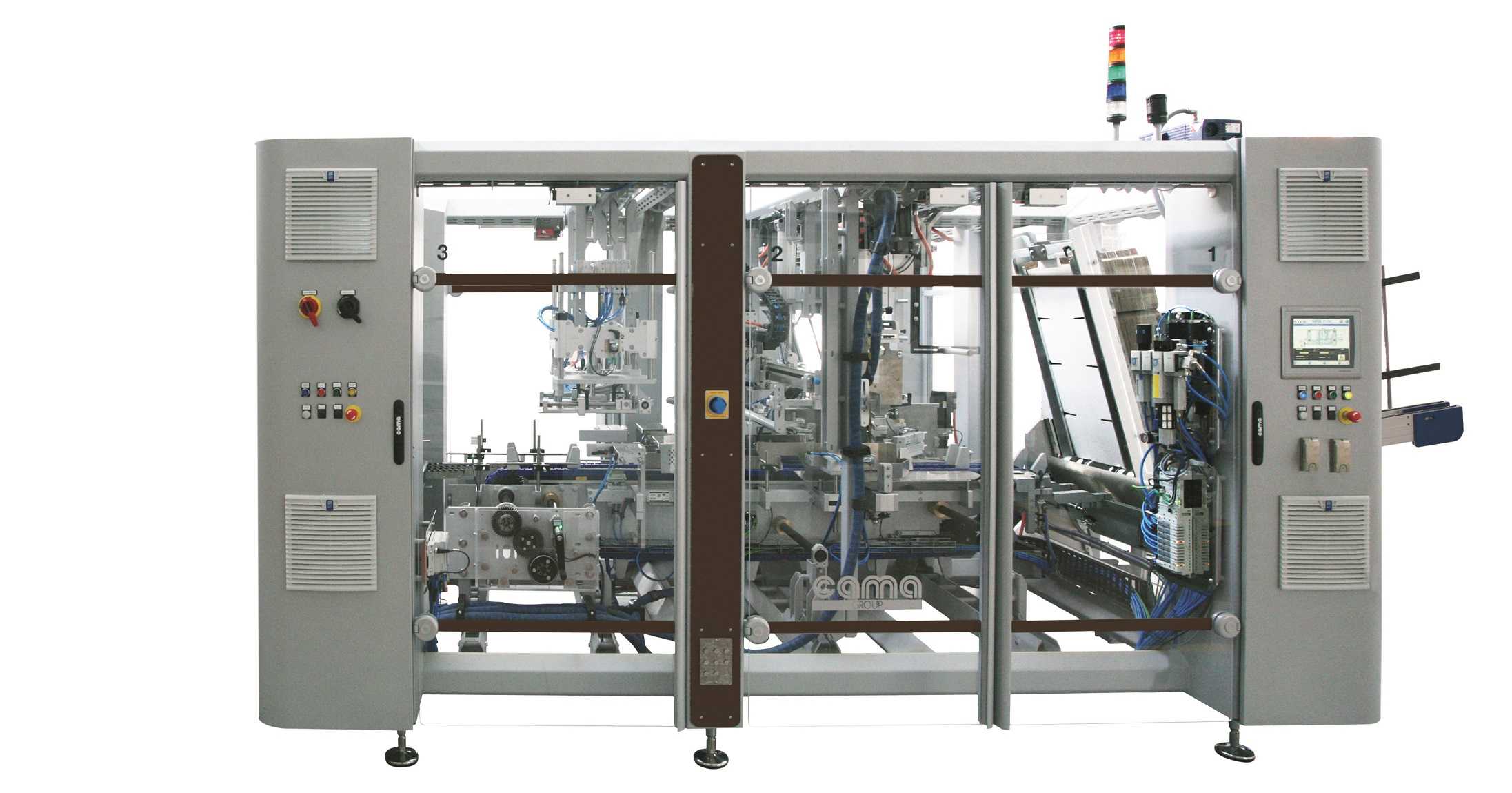

The outstanding innovative Cama Concept of Machines, called the Break-Through Generation, defines a new standard in the world of secondary packaging into paperboard or corrugated carton or case, including lean design, cabinet free technology, ergonomic features and user-friendly controls. Such most innovative Cama technologies are standard characteristics on the full range of Cama machines and systems.

All packaging lines and equipment in Oceania are supported and serviced by dedicated a Cama Australia team, based in Rowville, Victoria.

Cama Break-through Generation Systems make a step change in secondary packaging innovation

Cama stands on the Coffee market sector as the ideal partner, being able to supply both packaging machines and robots that are specifically engineered for the packaging business. The Cama robotic applications feature optimal, fast and gentle-handling solution that proved not to damage products, even the most delicate ones, and the special Smart Vision System that optimizes the management of the product by automatically selecting products according to pre-established dimension and arrival speed. This complete flexible line for the coffee industry show-cases Cama’s latest Break-Through Generation (BTG) systems. The impressive features of the new BTG models are the reasons why Cama has been able to make a step change in innovation in secondary packaging machinery.

The very latest technological innovations by CAMA Group mark a milestone in Research & Development, raising the standards in packaging automation.

- Higher Hygiene Standard:

– No hollow body;

– No horizontal surfaces;

– No water/dust/dirt retention;

– No tie wraps;

– Easily identifiable contamination;

– Easy cleaning.

- Open Profile:

– No bundled cabling (ICR, Integrated Cable Routing).

- Safe «Easy Entry» and Ergonomics:

– Zero «unsafe» Access;

– Increased accessibility.

- Flexible Frame and Reduced Footprint:

– Flexible modular configuration to better suit machine and factory layout requirements;

– Cabinet-free technology;

– Optimization of floorspace.

- Energy Saving Engineering:

– Optimized system design and components selection to reduce energy consumption.

- Fool-proof Size Change parts Recognition:

– User-friendly, fast and tool-less changeover;

– Reduced start-up time after changeover.

The iCapsulate Cama line in detail

The newly installed line by Cama in Blacktown, New South Wales, is composed of:

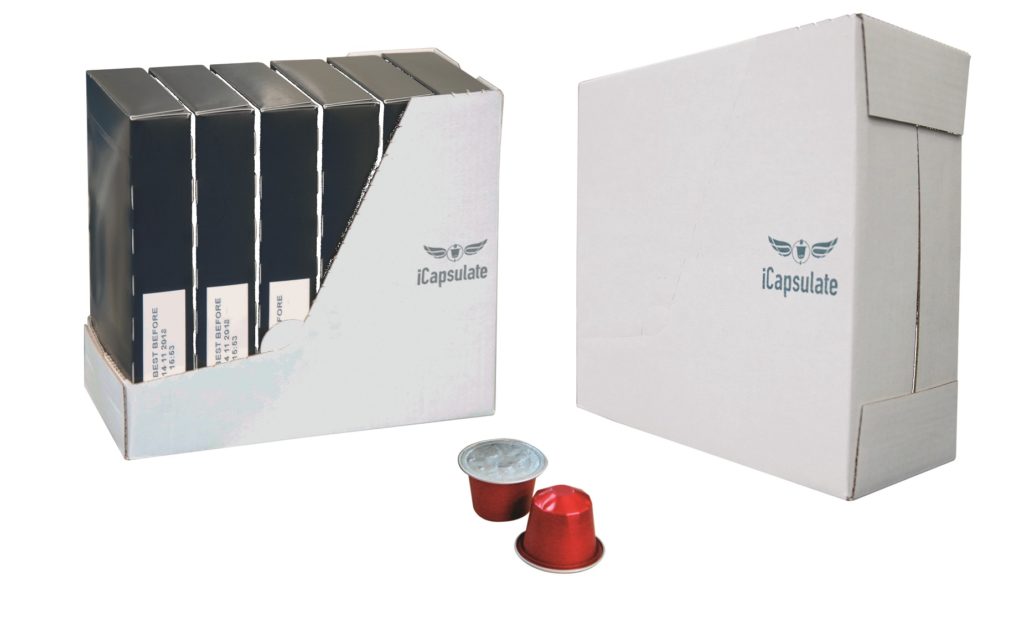

- a monoblock unit forming carton boxes, top loading capsules into boxes and closing boxes

- a wrap-around case-packer, loading boxes into corrugated SRP cases.

At the infeed of the Cama IF296 monoblock loading unit, the capsules are delivered on two lanes, upside down (seal down). One electronically controlled starwheel system for each lane phases the cups into an electronically controlled pocketed conveyor.

The boxes are in the meantime glue-erected from flat blanks by a twin head integrated electronic forming machine. The erected boxes are then transported and phased to the robotic loading area.

The collated products are then picked up by a two-axis robot with suitable head and loaded into boxes.

The boxes

The boxes, previously formed and loaded with lids in upright position, are conveyed to a robotic closing unit. The boxes are closed by hot melt, transferred to machine outfeed and then conveyed to the FW748 wrap-around case packer.

The boxes arriving on single lane are spaced by special accelerating conveyors and positioned in portrait position into the pockets fixed on a belt conveyor, driven by brushless motor.

The collated boxes are then deviated into the pre-erected cases; the flat blanks are fed from a magazine and erected into a flighted chain. After loading, cases are transferred to the following station, where case closing is completed and the cases are conveyed to the machine outfeed.

The project background and the successful outcome

Kane Bodiam talks about cooperation with the Italian company. “When we selected Cama, the timeline for the machinery was short, this project was to be the largest of its type in Australia. The machinery was built in a schedule that I didn’t believe was possible. The machine was in testing within a week of its arriving. I couldn’t believe how quick assembly was! We had support from Italy who provided exceptional training.”

“Based on the success of this project and for us to be able to build iCapsulate to the largest company of its type in the Southern Hemisphere in 1.5 years we have decided to produce now another format using the same machinery due to the success achieved with the current format.”

“We produce capsules for the largest companies in the world, Australia and New Zealand. The quality we manufacture cannot be replicated by anybody.”

Experience, technology and service provided by Cama build a long-term partnership; the technical solutions provided by Cama to iCapsulate and their trust in Cama lead to a lasting cooperation, underpinning the successful growth of both companies. This unquestionably excellent matching of innovative spirit and Italian flexibility and reliability has also gained international acknowledgement.