MILAN – Here is the interview that Davide Padelli, CEO of Gruppo Gimoka srl, gave us a few days ago.

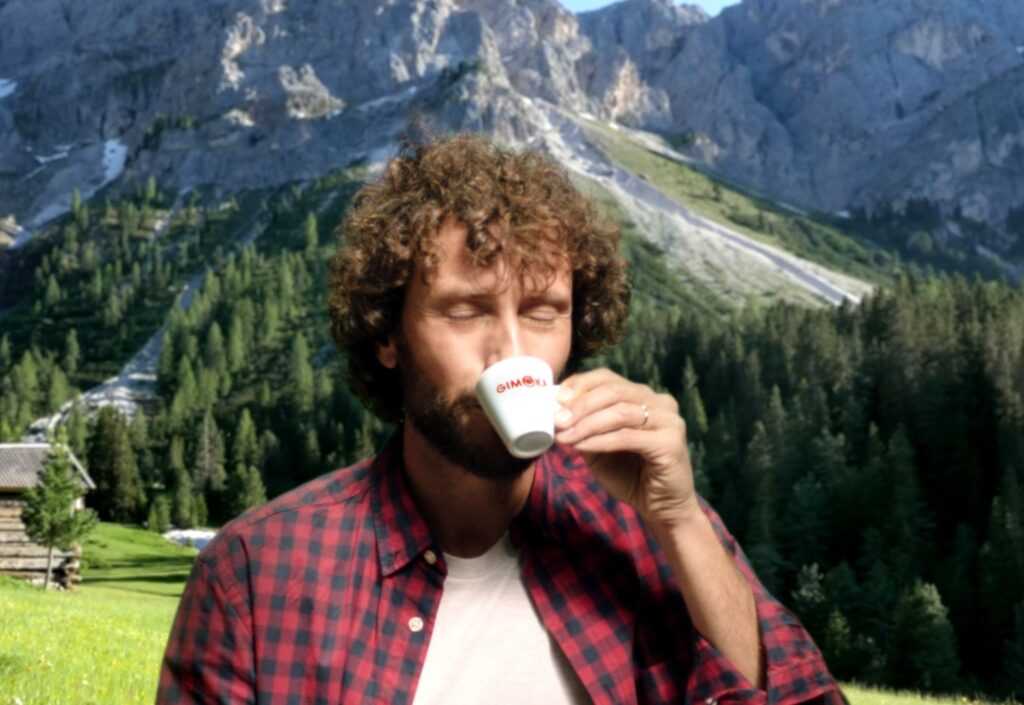

Comunicaffe International: Why has Gimoka decided to resume advertising on television, with two commercials on the RAI and SKY networks?

The decision to restart advertising the “Gimoka” brand on television is part of a broader investment strategy, whereby the Group is consolidating the position it has acquired over the years amongst the major European players and as the second most important Italian roaster, with over 500,000 bags of green coffee processed last year.

We have already made significant investments in technology, sustainability, but also in targeted acquisitions, which enable us to propose a full range of hot beverages to consumers. So far, our investments have focused mainly on innovation, supply chain control, production capacity and flexibility – unparalleled in Italy – as well as on the development of a multichannel approach.

Thanks to this industrial approach, today Gruppo Gimoka is already appreciated for its ability to cover all market segments with unique solutions. Now we must increase awareness and visibility of the “Gimoka” brand, to enhance its ability to penetrate the mainstream market. In this period marked by major changes in the coffee sector, the return of TV commercials consolidates Gimoka’s vision of being a brand that is able to produce high volumes and achieve significant market shares, by offering consumers a coffee that everyone recognises, at a price that is appropriate for all reference clusters.

You mentioned industrial investment. What does this mean exactly?

Our company is already indisputably recognised in the sector as a specialised partner for Private Label solutions and co-packing for many of the most important international and national companies in supermarket/large retail chains as well as for coffee roasters. This has been achieved primarily by investing in the industrial structure. Today, our annual roasting capacity allows us to double our current volume of roasted coffee, which means we can provide a constant flow of supplies to our B2B customers, without disruptions which in our sector cause problems when smaller or less technologically advanced suppliers are used.

We can rely on two traditional roasters and two hot-air flow fluid-bed roasters that use an innovative technology. Each type of roaster has a high hourly production rate and is energy efficient, allowing a continuous, uniform and high-quality roasting process, as the coffee beans are kept suspended in the air using only the air flow.

After having completed this important work at technological and industrial level, it was now important to also devote attention to the “Gimoka” brand, which has what it takes it to become a mass market reference brand thanks to an excellent quality/price ratio and a range of solutions that satisfy emerging consumption trends, ranging from innovation, by using aluminium capsules, to sustainability, by utilising compostable capsules, up to the selection of quality instant beverages (chocolate, ginseng, barley etc.).

What technical and organisational changes were required to collaborate with leading international players?

Collaborating as a partner of leading international roasting companies, in addition to both Italian and foreign supermarket/large retail chains, was a further stimulus to work towards achieving continuous improvement, both at technological and organisational level, thus guaranteeing production consistency and high quality standards. In addition to the two types of roasters I have just mentioned, our plan ̶ in industrial terms ̶ over the last three years has included investments of over €40 million in the industrial infrastructure of our group. Today, there are a total of 40 packaging lines, all state-of-the-art: very modern, efficient and highly automated. Thanks to this strong commitment, we have further increased production efficiency and the final quality of the product.

We are the only company in the sector that can handle all types of packaging, ranging from that for ground beans to the single-serve products having many different standards, which is an added value that is acknowledged by the market. To achieve these results, it is not sufficient to purchase machinery or expand production capacity. You must also improve the skills within the company, making the most of your resources and staff. We have developed know-how, focusing a great deal on research & development, and we have paid particular attention to continuity, from both a production and logistics point of view, the two being equally important. Today, we can pack any product having different brewing methods and the time has come to put to take full advantage of this business model, also with our own brands.

More than 40 packaging lines are a really high number. What types of products can you offer?

As I said, thanks to these investments, today we boast a supply capacity that is able to cover all the most common packaging solutions on the market, both in the coffee bean and ground coffee segments, without neglecting the single-serve products.

As I said, thanks to these investments, today we boast a supply capacity that is able to cover all the most common packaging solutions on the market, both in the coffee bean and ground coffee segments, without neglecting the single-serve products.

This year we installed three new lines of ground coffee, packed in 180 g, 200 g and 250 g soft packs. On the single-serve side, the company not only has the know-how and the technology to offer the most widely used compatible systems in the world (from k-cup, Nespresso, Dolce Gusto, to Firma, AMM, Caffitaly, espresso point); an extensive but also very comprehensive range … For many of these solutions we offer the “traditional” version, the oxygen barrier compostable type, but also ̶ as in the case of Nespresso ̶ the aluminium capsule. Just to give you further details: there are 8 packaging lines devoted to Nespresso compatible capsules and the same number also for Dolce Gusto.

Are they all in the Andalo Valtellino plant?

Valtellina has always been our reference community. It is here that my parents started on this exciting entrepreneurial adventure. There is a beautiful environment here which us, as entrepreneurs, are committed to safeguarding and respecting. Here, besides the roasting plants, we have three packaging plants (ground, whole-bean and single-serve coffee) and 3 of the 5 logistics warehouses which are required to deliver products to our customers.

The fourth plant is in Merlino, in the province of Lodi, and is the result of the recent acquisition of Univerciok, by means of which we have extended our expertise and offer in the market of instant beverage products (such as chocolate, ginseng, etc) and we are investing here, both in industrial and product development terms.

This gives the impression of an innovative and rapidly changing company, despite uncertainties, like those we have experienced this year…

Yes, the company is growing and continues to invest, despite the sharp drop in the out-of-home sector due to the Covid-19 pandemic. Investment in R&D and in industrial aspects is something that has characterised us for years and, as owners, we are confirming this, also in this lacklustre economic period.

Covid-19 has affected us all in many ways, but our family, as entrepreneurs, feels the responsibility to look to the future and not only to manage this specific phase. We feel we should set our sights on getting back to normal, although at times it is difficult to have a clear idea of when this will happen. To get over this period, we must believe in our company and continue to invest, not only on the industrial side but also on the product side, on the full package system machine-drink, commercial and distribution solutions, expanding and strengthening our structures and sales networks, both in Italy and abroad.

You mentioned earlier that one of the pillars of your business model is controlling the entire supply chain. What does this involve and what results have you achieved?

Yes, that’s right. One of the main strategic objectives of Gruppo Gimoka is to maximise the control of the supply chain, both upstream and downstream. As regards the coffee supply chain, we have more than 30 different varieties of coffee, which are purchased and selected directly in 17 different countries of origin, to allow us to produce more than 100 specially developed blends. Our company takes care of their transformation directly by using the most modern systems to ensure the lowest possible environmental impact. We also control the supply chain of primary and secondary packaging.

Thanks to this approach, the company has been able to face international competition and acquire greater control over all the delicate phases of the value chain, thus becoming a reference point for international players as well. We have achieved a turnover of €110 million, investing ̶ in recent years ̶ up to 12% of our turnover, a share that few companies in our sector and, generally in the manufacturing sector, reach in Italy.

Gruppo Gimoka is a articulated and constantly growing group. In which context and what role will the Gimoka brand play in the near future?

We believe that the repositioning strategy we are endorsing, also with the advertising campaign, will allow the Gimoka brand to better respond to the requirements of the mainstream market, which have changed considerably in the past few years. In particular, we are seeing changes in consumption habits of end users who, increasingly during and after the emergency period, are less faithful to major brands, thus this opens new growth opportunities for our brand.

Moreover, the dynamism of our segments, thanks to ongoing good sales of ground coffee and the upswing of single-serve products, confirms the leading role of the Gimoka brand in satisfying these needs, thanks to our ability to manage the production cycle of all types of coffee beverages. We have also noticed that in a crowded market in which players are being requested to invest, the e-commerce boom and increasing focus on sustainability, are new business opportunities for those who, like us, have already invested and are investing heavily now.

You were also amongst the first in your sector to believe in the importance of sustainability…

We all know that coffee is a crop which will be particularly affected by climate change in the coming years. Moreover, coffee is typically grown in developing countries, which entails important responsibilities, not only for the environment, but also for society. On the other hand, consumers are becoming increasingly well-informed and aware of these issues and, to an increasing extent, they integrate sustainability considerations into their purchasing behaviour.

As a player of growing importance on the international coffee roasting market, Gruppo Gimoka has taken on the challenge of environmental sustainability and the circular economy, in particular the commitment to reuse materials in subsequent production cycles, reducing waste to a minimum and the use of renewable energy sources. The group also promotes solutions for compostable products, developing packaging solutions that meet precise criteria, such as being recyclable or compostable and, whenever possible, mono-materials to facilitate recycling and reuse. However, we have gone even further as we have adopted a “Design for Recycling” approach. We have established a cross-functional study team, committed to developing effective solutions with the aim of fostering sustainable development and the circular economy. Some examples are the solutions using lighter and thinner materials, although maintaining the same functionality, paying particular attention to secondary packaging (that can hinder the compostability of the primary one, if not taken care of properly) or solutions that minimise logistics costs related to transport and storage.

From a social point of view, our focus on sustainability is completed by the inclusion of the St. Remio brand in the Gruppo Gimoka portfolio. The brand was conceived with the aim of bringing Gimoka ever closer to the concept of creating shared value. We have decided to invest in the welfare of disadvantaged communities ̶ particularly coffee-growing women in Rwanda ̶ not only to ensure better living conditions for them, but also to provide instruments that can allow them to become economically and socially independent. We believe that supporting even the most disadvantaged stakeholders in the coffee value chain can only benefit everyone, especially in the medium- to long-term.

The Gruppo Gimoka logo