MILAN – Twenty-seven years old Giacomo Spreafico is the son of Enrico Spreafico (on the left in the picture above), owner of Spreafico Srl, a Lecco company specialized in the manufacturing of capsuling machines. Giacomo is part of the company, coordinating its business operations.

We have asked him how the company was founded and what are the strengths of the current production line. Stefano Pavan, a newly hired sales representative, then gave us a few details on the market in which Spreafico operates and on its growth prospects.

Giacomo Spreafico, in just a few years your company has become one of the most important players of the industry, how did you get to this point?

“Spreafico was founded in 1975 as a company specialized in precision machining for third parties. Over the years Spreafico began constructing increasingly more automated but generic plants, for the construction of bolts and screws, presses, machines and components for the food industry, and so on. In 2008 we had the chance to build a machine for the filling of capsules for espresso.”

How did the first request arrive?

“It arrived from an important and famous client, Gimoka. My father immediately sized the opportunity of creating something new, understanding that it had the potential to become a core part of our business. At the same time, in order to build these machines, we needed those skills we had gained in the designing and manufacturing of the automated machines that already were the flagship of Spreafico.”

What is your role in the company?

“Since I entered the company, I have always worked in the procurement department, but I’ve also helped my father in managing the staff and the company. This year I have begun to handle the commercial side of the business, also thanks to the hiring of Stefano Pavan, that I wanted to join me in this activity. Our goal is to have Spreafico products be known in the markets where Spreafico is not yet present, especially in France and Germany, but also in Asia, which is a huge market.”

The whole world is now focusing on the compatible capsule …

“Yes, it is a global trend, we have requests from the whole world. The reason is that it is not easy to prepare an espresso abroad, whereas the capsule makes everything easier, with consistently excellent results in the cup.”

Only capsules for espresso?

“Not just for espresso. We have been selling plants for a long time to an important Canadian client, that works with capsules which are compatible with the Keurig system, that is, for American style coffee.”

What are the strenghts of Spreafico and its machines?

“Spreafico’s strenghts are mainly two. Firstly, we have kept our historic internal production unit – the mechanical workshop – which allows us to create parts of the components on our own, and it is very helpful to handle urgent orders, both internal and external, in a very dynamic and flexible manner. And, secondly, the professionalism of our employees. Today we are 38, in 2008 we were only 10: an exponential growth.”

How long does it take to build a capsuling machines?

“We can deliver a machine in two months from the request, we are fast.”

How important is it to anticipate the needs of the market and how important is Research & Development for Spreafico, in a field that seems static: there are no new capsule standards …

“In the last two years we have launched a Research & Development department, with the goal of increasingly improving our machines, making them reliable and sturdy, to better meet the requests of our clients, who are asking for machines that never stop producing and can keep working 24/7. Even though, of course, in all our manuals we detail how to correctly service the machines. These operations, however, don’t take too much of the time that should be dedicated to the preparation of the capsules. Our machines need very little maintenance: it’s one of our strengths.”

Do the capsuling machines come with a warranty?

“Of course, we give a one year warranty.”

Stefano Pavan, how is the market right now?

“We are growing. We are operating a lot in the international market, that now makes up 60% of our orders. Of course that is not just coffee, we are receiving a lot of requests for all of the soluble products, which means ginseng, chamomile, tea, tea leaves. And this allowed us to improve our machines, as there is a difference between working with coffee and with soluble products. These are machines exclusively built for these products because, unfortunately, they contain sugar, an element that can cause problems to the components, which need to be kept clean at all times. The operator needs to be precise and properly service the machine, too. Although it is definitely not a complicated operation, just a damp cloth and warm water.

Generally speaking, we are trying to be ready, analyzing market trends and trying to anticipate technological solutions. As Giacomo already mentioned, the market lets us know what it prefers and thanks to internal testing we find an effective and permanent solution to apply to our plants. We work with small and medium-sized businesses, as they see us as similar to them, with similar size and structures, but we have also been contacted by big groups, as they know these machines aren’t easy to make and this is our only industry, so we are very specialized.”

What’s Spreafico product range?

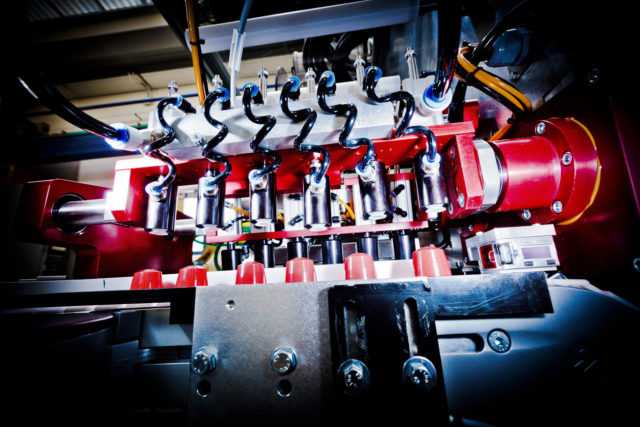

“The entry level machine, that doesn’t sell a lot nowadays, is the single lane, 70 capsules a minute, then we have the 2 lane, 120 capsules a minute, the four lane, 240 pieces a minute and our flagship: the 6 lane machine, for 360 pieces a minute. The request from our most important clients is for a 12 lane machines, for 720 pieces a minute.

Why 12 lanes? Aren’t two six lane machines the same thing?

“Subcontractors prefer two six lane machines, so they can keep working if there is a failure on one of the two machines. And, having different clients, they can also work on different brands or products on the two machines. Two six lanes machines are definitely more flexible. But the biggest clients, the ones that work for the large-scale retail channel and need to produce a lot, prefer the bigger machines. And many of these purchasers look at our German competitors, who only produce big machines.”

There is a foreign competition …

“Yes, but not for our target, for our type of machines we only have Italian competitors. But we have a very in depth, comprehensive knowledge of the market and we know how to handle it.”