Host exhibition has closed on October 27th very positively for Goglio. The new range of capsule machines has been introduced, gaining a remarkable success thanks to the many visits on the stand during the fair. The complete System is once more the nub of the offer, and the trademark Fres-co System, applied to coffee, assures a skilled and unique service to customers.

The GCap range includes lines designed to easily and flexibly manage capsules of different shapes, with speeds of up to 120, 240 and 360 capsules per minute.

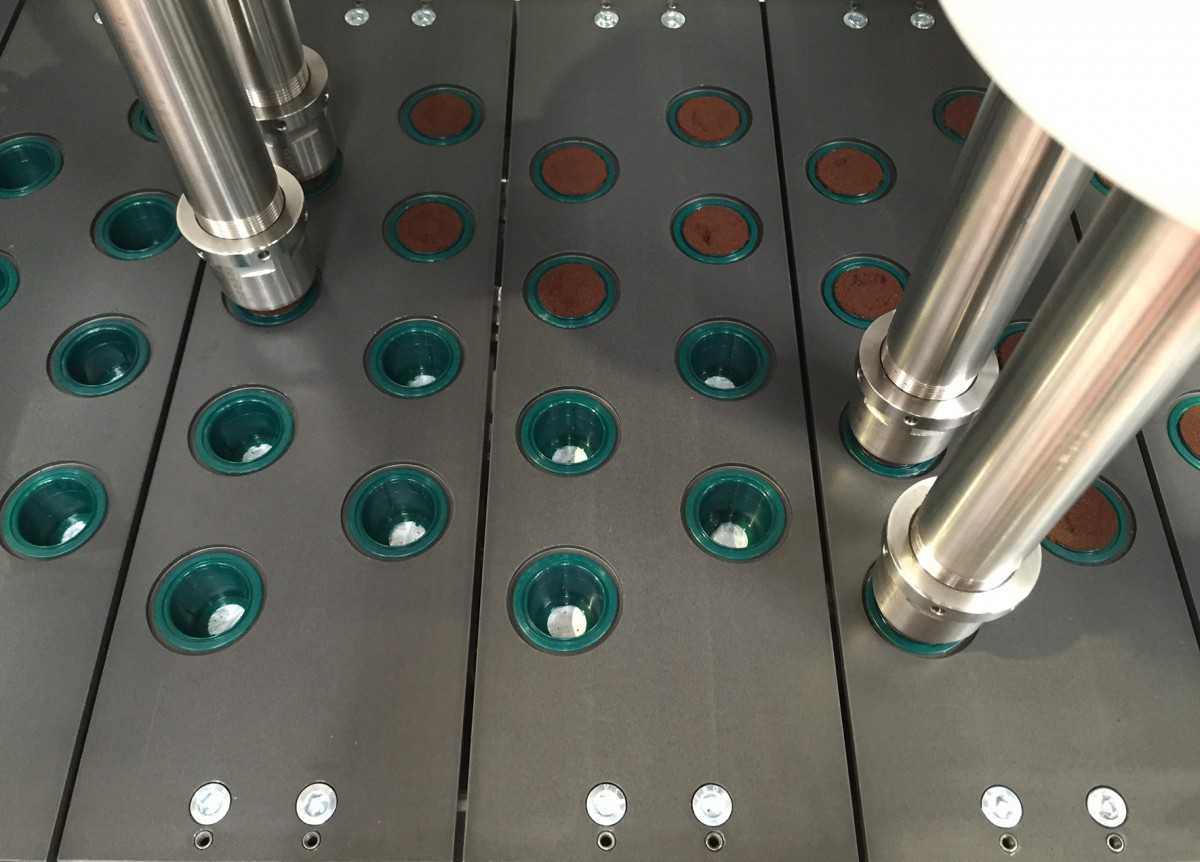

The pan-feeder guarantees an excellent product homogeneity; the filling, pressing and sealing groups work with the typical “chessboard” layout in order to optimize at its best the use of material in reel and minimize production waste, while a nitrogen tunnel leads the capsules from the filling station to the lid sealing area.

A great attention has been devoted to maintenance and cleaning: extractors located in the filling and pressing area remove powder from the sealing zone while a brush, placed under the conveyor belt, collects in a tank possible waste of product and then extract it.

Besides all groups are assembled on tracks, for a total extraction to ease regulation, maintenance, cleaning and reel changes are reduced, simplifying the operator task and maximizing production efficiency.

Further distinctive characteristics are the stainless steel frame, load cells with direct feedback to augers for weight control and cameras to verify the central position and the correct sealing of the top lid.

Discover all details about the lines on www.gogliocap.com.