MILAN/ANDALO VALTELLINO (province of Sondrio) – One of the main proposals presented by Gruppo Gimoka at Host 2019, taking place at Fieramilano (Rho) from Friday 18 to Tuesday 22 October, is multi-faceted innovation in its endeavour to achieve sustainability.

Sustainable innovation in all stages of the process: starting from a design for recycling approach – for example using alu-free mono-materials (fully recyclable) – combined with weight reduction, up to the use in its packs of compostable materials, derived from plant sources that are not used for human nutrition.

Gimoka: Coffee instinct is going green

Using a new payoff for the occasion, Coffee instinct is going green, the Group positions itself at Host 2019 as a reference player that is able to offer a fully compostable solution (pods and packs) for ESE and Senseo ® (*) compatible systems in the single-serve market.

Using a new payoff for the occasion, Coffee instinct is going green, the Group positions itself at Host 2019 as a reference player that is able to offer a fully compostable solution (pods and packs) for ESE and Senseo ® (*) compatible systems in the single-serve market.

The filter paper is produced using a special natural origin fibre (PLA based on cellulose and polylactic acid) that is heat-sealed and certified as being compostable by Ok Compost in compliance with the European standard EN 13432, besides being certified 100% OK Bio Based (4 stars).

Even the flow packs, in special material sold exclusively to Gruppo Gimoka, are made of plant fibres that are OK compost certified by TÜV Austria.

A unique packaging

A unique packaging in terms of benefits offered which, besides providing an oxygen barrier preserves the coffee aroma for a long time, is unaffected by the colour restrictions of other fibres and lends itself to being used in the excellent packaging to exploit the marketing potential of the single-packs it contains.

A unique competitive edge for Gruppo Gimoka, both compared to normal paper pods – usually non-compostable – but in particular when compared to the traditional coated-aluminium packs that cannot be recycled and must be disposed of in the unsorted waste. Gruppo Gimoka thus enhances its green strategy by combining environmental sustainability with greater added value features like quality of coffee in the cup, practicality and maintaining the product’s characteristics over time.

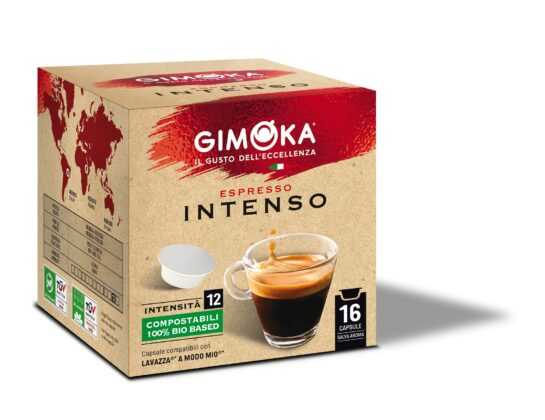

Bio-based compostable coffee capsules

Present at the stand are also the OK Compost certified 100% bio-based compostable capsules compatible with Lavazza A Modo Mio®, with an excellent cup quality, as well as with 100% bio-based compostable Nespresso® compatible capsules.

All Gruppo Gimoka capsules feature an aroma protection, meaning that they are compostable but have an oxygen barrier, therefore they can be disposed of in the wet waste to be treated in an industrial composting plant.

All Gruppo Gimoka capsules feature an aroma protection, meaning that they are compostable but have an oxygen barrier, therefore they can be disposed of in the wet waste to be treated in an industrial composting plant.

The bouquet of aromas of the coffee is therefore safeguarded in an optimal manner, even over time, due to its longer shelf-life, without requiring overwraps. The coffee is packed in compact packages that take up less space on shelves and during transportation.

A proposal that seeks to address consumer targets that are more conscious of sustainability issues and that can also represent a very interesting product range extension for Gruppo Gimoka’s private label customers.

Emphasis on sustainabilitywith Australian brand St Remio

Gruppo Gimoka’s emphasis on sustainability is crowned by the recent inclusion in its brand portfolio of the Australian brand St Remio, which is strongly committed to ethics as it supports coffee farming cooperatives in Rwanda, thanks to two-year support programmes focused on tangible objectives in favour of women. St Remio’s entire UTZ certified offer will be presented at Host in the Group’s stand.

Gruppo Gimoka is one of the most sustainability-focused companies in the sector

Gruppo Gimoka ranks amongst the most sustainability-focused companies in the sector, as it is continuously striving to improve the sustainability of its products, by complying with the highest standards, ranging from the United Nations Sustainable Development Goals to the FAO policies on sustainable agricultural practices and the circular economy, not forgetting the European Strategy for Plastic that was adopted in July 2018 and the UNI EN13432 standards, thus working on all fronts: raw materials, production processes, packaging as well as use and disposal of the product.