OZZANO DELL’EMILIA, Bologna, Italy – IMA Coffee strives to answer the needs of the industry and engineers top-quality solutions to enhance the performance of their customers. By following the trends closely and raising the technological level of the equipment, IMA enables customers to achieve their targets and responds to the market’s evolving demands. The latest example of IMA Coffee’s ability to innovate and push back the boundaries of capsule filling and sealing is called Synkro.

Flexibility, speed and a clean design concept

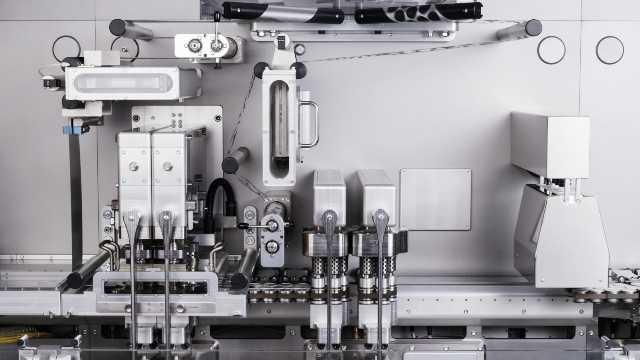

Synkro implements the latest technologies to deliver the following key benefits: high-speed performance, space-efficient design, unprecedented flexibility in handling all types of capsule, whatever they are made of. Starting with the design, this machine is compact and enables easy access to operators for maintenance or cleaning operations. In particular, the pull-out dosing unit is quick to clean whenever necessary. The machine’s footprint is relatively small for the high processing speeds that are reached, ranging from 800 to 1200 ppm.

In terms of flexibility, there are many aspects which make Synkro probably the most versatile, high-speed capsule filling and sealing machine available today. Principally due to the magnetic shuttles operating independently of one another, Synkro will adapt to all needs. Bulk-fed, on trays or in stacks, whatever the material or size of the capsule, anything is possible.

The most significant aspect of the machine’s versatility depends on the different dwell times that are achieved at the different operating stations. This enables the customer to set perfect parameters according to the production scenario, adjusting each single operation and optimising the final product quality. For example, the sealing system parameters – time and pressure – can be changed according to the material to be sealed. Moreover, the machine can be fitted with a variety of different sealing systems, allowing customers to select the most appropriate solution based on materials used and the product they are processing.

Automation and accurate processing

Cutting-edge automation technologies combined with the clean design of Synkro allow for non-stop production. Both semi- and fully automatic reel-feeding are possible. Pre-arranged to connect to loading systems via AMR (Autonomous Mobile Robot), the machine also features an automatic reel-splicing system.

Synkro also benefits from an innovative dosing unit that implements pre-compression to compact the coffee during capsule filling for a homogeneous product; this guarantees consistent dosing throughout each batch. Accurate weight is an easy target to respect thanks also to the on-line weighing system which checks each capsule and feeds data back to the dosing unit if automatic adjustments are required. Last but not least, the dosing unit’s off-set design minimises the distance between capsules for important savings on packaging material.

Exploit superior potential

Synkro has been developed to boost the capsule filling and sealing potential of companies looking to reach higher targets and exploit the variety of demands today’s market makes of coffee capsule producers. Independent magnetic shuttle transfer, synchronised processing which can be adjusted time after time, automation systems and innovative mechanisms to ensure reliably consistent quality, and a clean, modular design concept are all factors that make Synkro the superior solution.

For more info click here.