OZZANO DELL’EMILIA, Bologna, Italy – Sustainability is becoming less of an option and more of a requirement for businesses in the coffee industry. This is especially true in the single-serve market, where plastic waste and the environmental footprint are most visible to the consumer. IMA Coffee, consisting of IMA Coffee Packaging and processing arm IMA Coffee Petroncini, is committed to playing its part in helping coffee businesses improve the sustainability of their single-serve products. IMA has created the Coffee Hub to leverage its expertise at every step of coffee processing and packaging and serve the coffee industry from A to Z as a one-stop answer to large and small coffee producers worldwide.

The benefits of such an approach are: market-leading competencies, industry experience, and application-specific know-how encompassing all stages of coffee handling, processing and packaging.

IMA aims to work alongside companies and multinationals that want to handle different types of products reducing their impact on the environment.

As a manufacturer of automated solutions, IMA improves sustainability by minimising the impact equipment has on the environment, and by helping customers to develop new, sustainable products.

Recent developments in the materials used to produce compostable coffee capsules have made them a more practical option for many businesses, who in the past were deterred by their short shelf life. The material used for compostable capsules has improved over the last year in response to increasing demands for greater sustainability. Handling these materials is now a lot easier for IMA packaging machines.

Contributing to the company’s vision

Contributing to the company’s vision

Recently IMA Coffee Packaging delivered a filling and sealing machine for compostable coffee capsules to American start-up Smile Beverage Werks.

Smile Beverage Werks is a Public Benefit “B” Corporation aiming to make single-serve coffee more sustainable. Its mission is to make responsibly sourced, exceptional coffees in the most environmentally friendly coffee capsules for the brand Smile Coffee Werks and for private label customers.

However, compostable coffee capsules have traditionally experienced two issues: on one hand preserving the freshness of the coffee, on the other hand maintaining the capsule’s structural integrity. Refusing to compromise on quality, Smile Beverage Werks sought out material and equipment suppliers that could bring its vision to life.

Performance, flexibility and ad hoc solutions.

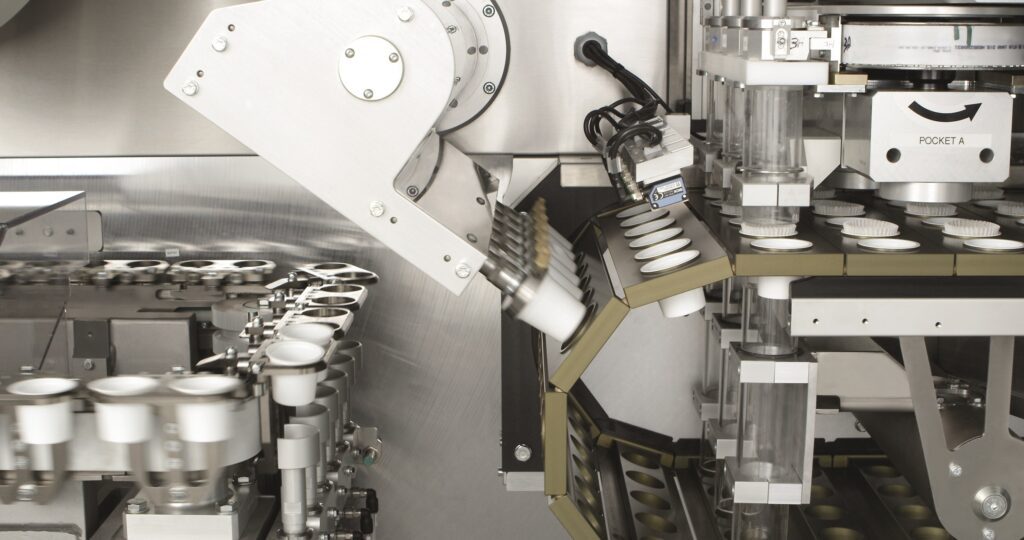

Answering the primary requirements expressed by Smile Beverage Werks, IMA supplied its 595 capsule filling and sealing machine. Capable of processing up to 450 capsules per minute, this high-speed solution will theoretically handle 120 to 130 million capsules per year. Designed to handle all types of products or materials, not just plastic and aluminium, equipment developed by IMA is able to fill and seal all capsule types on the market. Moreover,

IMA can work upstream with the capsule and material suppliers to implement changes to the material or machinery as needed.

In the case of Smile Beverage Werks, IMA Coffee Packaging applied an ultrasonic sealing process. This solution provides superior flexibility compared to thermal heating for the type of compostable product the company wanted to produce.

Additional flexibility is achieved thanks to the machine’s modular design, allowing for a variety of sealing systems for different capsule types, materials and dosed products. The machine also handles inner components to be placed and sealed inside the capsule before dosing, such as plastic filters, paper filters and bottom lids.

In the customer’s words

We asked Michael Sands, CO-founder and CEO of Smile Beverage Werks, a few questions to illustrate the project and understand his opinion on working with IMA.

What were your main objectives for this new project?

“We needed to get to market quickly on a commercial scale with a new environmentally friendly capsule technology.” Sands said. What they were looking for in a partner included pragmatic R&D proof of concepts, the ability to adapt quickly and recommend and implement changes. The equipment itself had to guarantee an output of at least 400 capsules per minute.

Why did you choose IMA?

“We chose IMA Coffee Packaging as our equipment partner, based on their industry reputation for quality, their R&D capabilities, and their insight with regard to the emerging sustainability market and the support thereof.”

From a sustainability perspective, IMA not only provided a machine able to handle compostable materials, but was also able to provide a service customers are requiring more frequently, the Remote FAT. Using dedicated platforms, IMA enables the appropriate checking procedures of the plant to be carried out without on-site presence of the commissioning technicians. Using live streaming, the customer interacts by participating in online webinars equipped with all the most advanced tools.

How have IMA solutions responded to Smile’s needs?

“IMA quickly figured out changes to the machinery needed in order to make the technology work,” Sands said. “They worked closely with us to find all technical solutions, so that we can use a well-known and highly regarded machine at output levels that support industry standards and economics.”

To achieve this, IMA Coffee needed to make sure its equipment could process the capsule material, which requires cooperation with the capsule and material suppliers.

IMA Coffee has purposefully built strong relationships with material and capsule suppliers around the world for this exact reason. In fact, several material suppliers involved in this project recommended IMA Coffee Packaging to Smile Beverage Werks.

IMA Coffee’s R&D lab was able to help Smile Beverage Werks find the right set-up, make small changes to the product with the capsule and material suppliers, and adjust the machines in order to suit this type of product.

Are there any more projects in the pipeline?

“We expect this category to grow fast with additional capacity to be added and new packaging options to help disrupt and grow the 15 billion annual North American coffee capsule market,” Sands said. IMA will continue working with Smile Beverage Werks as the start-up grows and expands. Sands believes demand for sustainable single-serve products will only increase and Smile Beverage Werks is ready to meet that demand.

Despite its European origins, IMA has built a strong presence in North America, with customers across the United States as well as Canada. This is an important market for the coffee industry, where IMA Coffee stands out for offering a turnkey solution, from green bean intake through to cartoning and end-of-line solutions.

For more information, visit www.smilecoffeewerks.com or www.coffee.ima.it

For more information, visit www.smilecoffeewerks.com or www.coffee.ima.it