RIMINI, Italy — World-leading designer and manufacturer of automatic processing and packaging equipment for numerous industries, IMA Group has recently established the Coffee Hub, a cluster of specialist brands, each providing a key slice of the experience and expertise needed to serve the coffee industry from A to Z. Comprising a handful of expert companies and supported through consolidated, strategic partnerships, IMA can now address any issue facing coffee producers.

Spreafico Automation, part of IMA Coffee Hub, headquartered in Calolziocorte, Lecco, Italy

It offers a selection of solutions with different speeds and features in order to be suitable to respond to any production need. With a well-established reputation for the reliability and strength of its machines, the company takes advantage of the mechanical skills available in the region in which it is based.

Spreafico is highly specialised in designing machines for the packaging of coffee capsules and soluble products

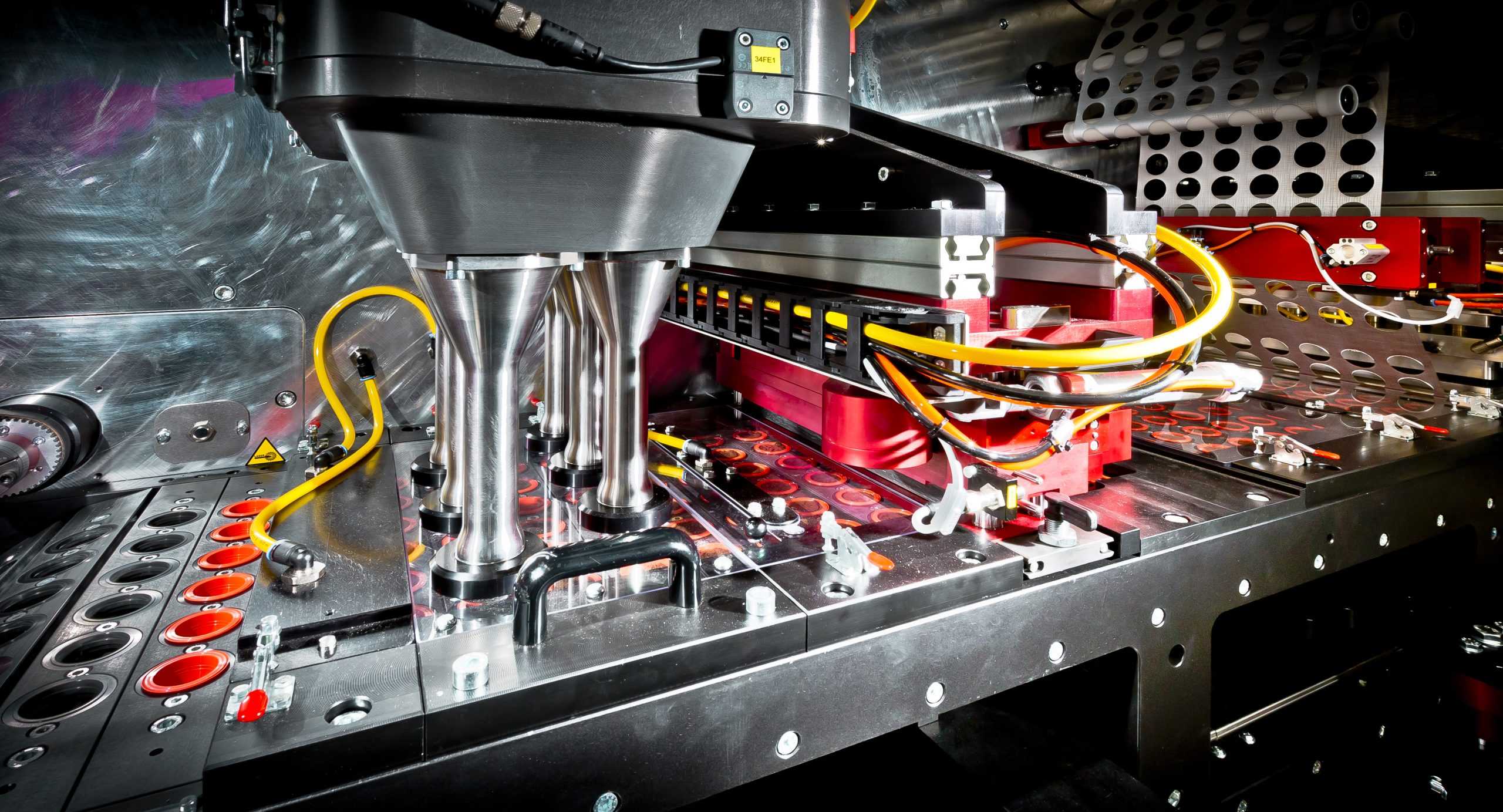

Spreafico designs and manufactures last generation linear machines, from 2 up to 10 production lines. Capsules can be closed at the top with aluminum film, micro perforated, filter paper, triplex coupled, PP lid. Possibility of inserting filters and diaphragm into the capsule and on its bottom. According to the machine configuration, speed can vary from 120 to 600 capsules per minute.

Together with capsule-filling equipment, Spreafico is renowned for building special machinery to customise standard capsules according to specific requirements and is the undisputed leader in this field thanks to consolidated mechanical expertise and unmatched technical competences.

Working close to capsule producers, Spreafico has implemented a wide range of technology to assemble all capsules according to customer and market needs. The Spreafico capsule preparation machines can be fitted to work with all kinds of capsules, self-sealing or non self-sealing, with different thermoplastic, compostable or biodegradable materials.

The company’s flexibility allows it to manufacture units for the insertion of plastic filters or for the cutting and sealing of paper or aluminum filters, alternatively on the bottom or on the outside of the capsule

Spreafico, at Host 2019 has unveil the brand new machine for the filling and packaging of Nespresso® compatible aluminum capsules. Being one of the most common capsule styles on the market, it guarantees both a top quality final product as well as its recyclability, as the capsule is completely free from plastic laminates. Based on the afore mentioned features, that have made its success, the aluminum capsule requires dedicated packaging machines, guaranteeing a particularly gentle process, starting from the feeding phase up to filling and sealing.

Spreafico Automation boasts a unique know-how in this specific segment being also supported by the experience gained in IMA Coffee GIMA

where applications for compatible aluminum capsules have been developed on high-speed machines. These machines are perfectly tailored to the market needs – medium-high production speed encompassing at the same time all the Spreafico’s well known technological features guaranteeing great reliability and top quality product with extended shelf life thanks to less than a 1% residual oxygen within the capsule.

The first Spreafico modular machine will be presented at Interpack 2020. Encompassing a host of clever upgrades and innovative solutions providing the highest efficiency and guaranteeing the best product quality, the machine will be on show with the Nespresso® compatible aluminum capsules version. The line will be completed with a dedicated cartoner.