MILAN – After celebrating 100 years of activity in 2019, Petroncini has spent the new year working on a series of innovations coming for roasting factories, with the goal of coming closer to customer needs.

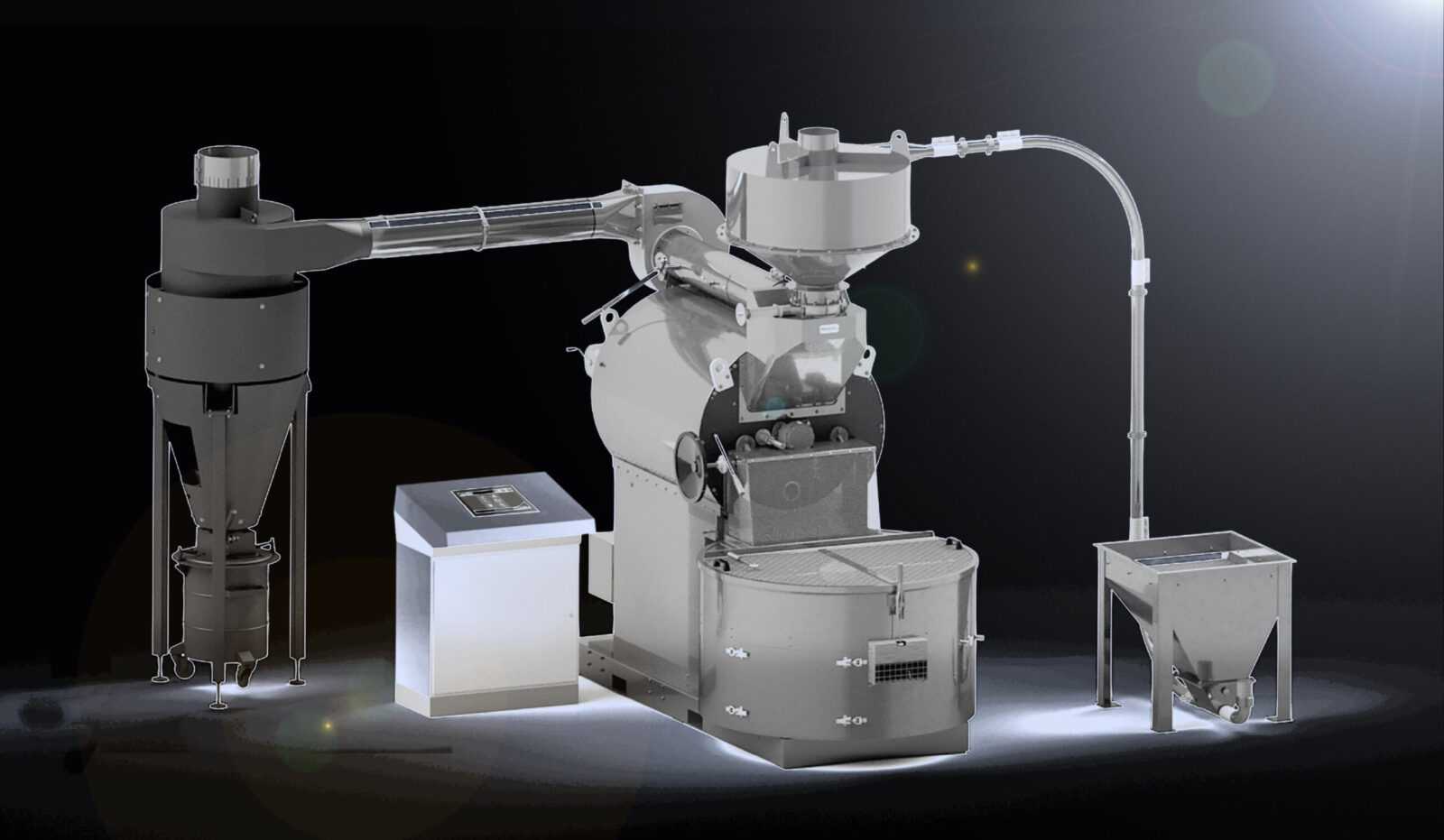

Today, Petroncini launches the new TTG 60, specifically designed for flexible roasting times, thus enabling a deep and homogeneous bean development in order to enhance the full-bodied and aromatic characteristics of the final beverage, typical of Espresso, Specialty and high-quality gourmet coffees.

TTG 60: Reliable and cost-effective machine

Its hourly capacity of about 240 kg and the manual management of the working phases make TTG 60 ideal for small-scale industrial roasters who don’t want to give up the pleasure of artisan roasting of their own coffee.

TTG 60 is an easy-to-use, reliable and cost-effective machine enabling complete handling freedom of the roasting, combined with the guarantee of the highest manufacturing quality and long-life operation of devices installed.

The equipment is easily set up so that time-to-commissioning and maintenance operations are definitely reduced, ensuring high profitability standards.

Old traditions. A new vision

Petroncini is renowned worldwide for the quality of its roasters. The innovation applied to these machines over the years has in no way affected the sturdy qualities of the materials and the reliability of the original product. On the contrary, it has set out to put the roast master at the centre of the process, making him increasingly aware of the technology and giving him all the tools necessary to improve skills in personalising a top-quality roasting profile, so that he can turn his creativity into reality.

Thus, the new Petroncini machine concept faithfully respects the essentials of the company’s long-standing tradition as a coffee roaster manufacturer but leaves the master roaster full control over the roasting process.

TTG 60: Easy to operate. Easy to customize

As a consequence, the NEW TTG 60 has been developed: the suitable solution for artisan roasting factories with higher quality requirements. The TTG 60 allows the roast master to manage coffee temperature, drum rotation speed and air-to-bean ratio, therefore letting him vary the method of transferring heat to the bean, achieving the desired balance between convection and conduction.

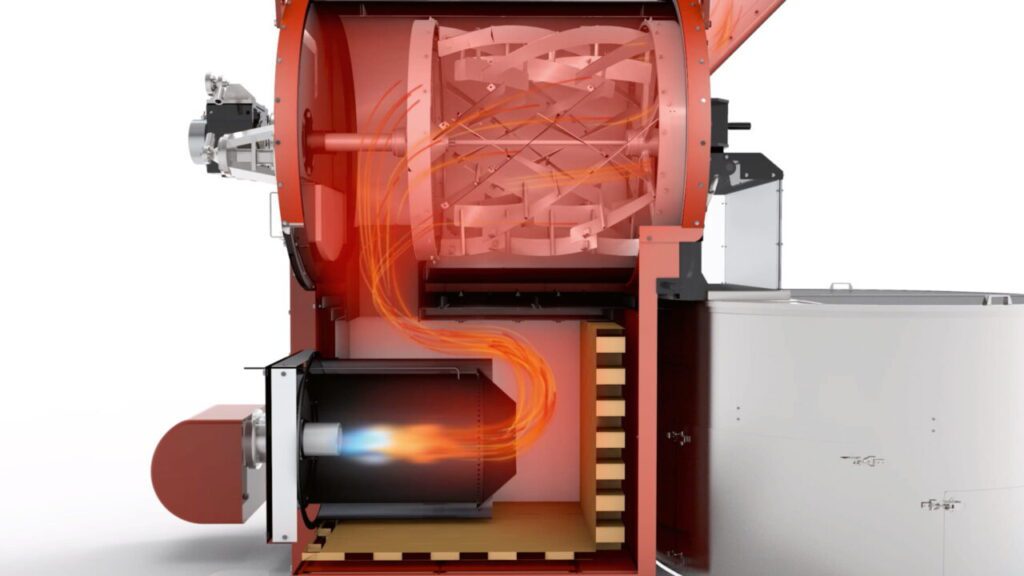

Managing the roasting variables according to the desired end product, the roast master is now able to transfer heat through the soft conduction with the insulated drum surface and with the powerful heating convection, through the massive air flow volume that can be handled inside the drum.

The heating chamber, made with very thick material, guarantees perfect and homogenous mixing of the roasting air, resulting in reliable machine performance and repeatability of roasting profiles. We can thereby succeed in achieving countless sensory profiles, developing the coffee’s deepest aromas, from light roasting to the very darkest.

Another benefit of this strong roaster is at the very heart of roasting, namely the way in which the heat is transferred to the coffee beans. The thermal energy cycle adopted by the TTG 60 allows for the gentle drying and caramelisation of the coffee sugars, avoiding direct contact between heat source and modulating burner and the roasting chamber. This makes it possible to control the amount of heat transferred to the bean and reduce uncontrollable thermal inertia as much as possible.

Having good thermal insulation of the external surfaces allows this roaster to offer a “soft” roasting, that means controlling the heat distribution to the beans, taking care of the raw materials so as to achieve the highest quality aromatic profiles.

At every phase, an effective solution

TTG 60 is equipped with two independent suction systems, one for roasting and one for cooling, so that the two phases can be carried out simultaneously and in full capacity between one batch and the next, without neglecting the cooling phase. Effective cooling must quickly stop prolonged internal reactions that might otherwise over-carbonise the sugars, resulting in too much bitterness and hints of burned taste.

The TTG 60 cooling system reaches ambient temperature in less than 3 minutes. As a result of the attention paid at every phase, this machine guarantees minimal product and weight losses. In addition, TTG 60 is equipped with technological components that ensure maximum security during the process and different eco-friendly systems aimed at reducing the Carbon Footprint.

The maximum expression of the roasting values.

Maestro is the Petroncini software applied to the TTG model and it can be operated directly at the roaster or via remote control. Maestro has been designed and developed to give the roast master an easy-to-use, intuitive, and reliable interface to help him handle roasting at his discretion. Maestro for TTG 60 includes the two configurations, Classic and Avantgarde, combining the complete freedom of manually roasting with the possibility of pre-setting the roasting recipes.

The temperatures and other parameters are shown in the trends summary, where the user can control roasting curve and current temperatures, monitoring the Rate-of-Rise and recording the first and second Crack temperatures in just one click. The Avantgarde control is ideal for those who prefer to pre-set the different desired roasting profiles.

It is a valid partner on the way to achieving a product that is constant from a quality viewpoint and repeatable in terms of taste and aromas, being able to determine and establish right from the start what the characteristics of the end product will be, in terms of taste, olfactory, organoleptic and even physical characteristics, that is, the actual appearance of the product.

The roast master can set up to 8 roasting steps for each roasting profile saved and register up to 99 roasting recipes in the system

In addition, he can simply record and export the roasting profiles on a USB drive or save the recipes, export the roasting data, organise and analyse them on a PC at any time through an application developed by Petroncini, collecting a back-up of 5 years of production. MAESTRO allows for remote connectivity and remote assistance.

Discover more at this link.