Share your coffee stories with us by writing to info@comunicaffe.com.

As food producers, coffee roasters have to meet high quality standards. Origin and processing of the green coffee must be fully traceable. For this reason, Neuhaus Neotec, one of the market leaders in the roasting technology, supplies with NN Quality Management (NN-QM) the first network-based system for recording and filing the roasting data.

The software can be easily installed in both new and existing roasting plants.

Since NN-QM operates network-based, the data of the roasting process can be called up via browser from any office. Further local software installation is not necessary.

With its innovative “pure-web” programming, NN-QM does not depend on specific software or operating systems; maintenance or updates are not necessary. This solution is therefore particularly fit for the future, because the software can always be adapted to different requirements.

Important support for certifications

With NN Quality Management, coffee roasters have an ideal tool for quality management. NN-QM offers the user a fast and convenient access to all quality-related data – directly during the roasting process.

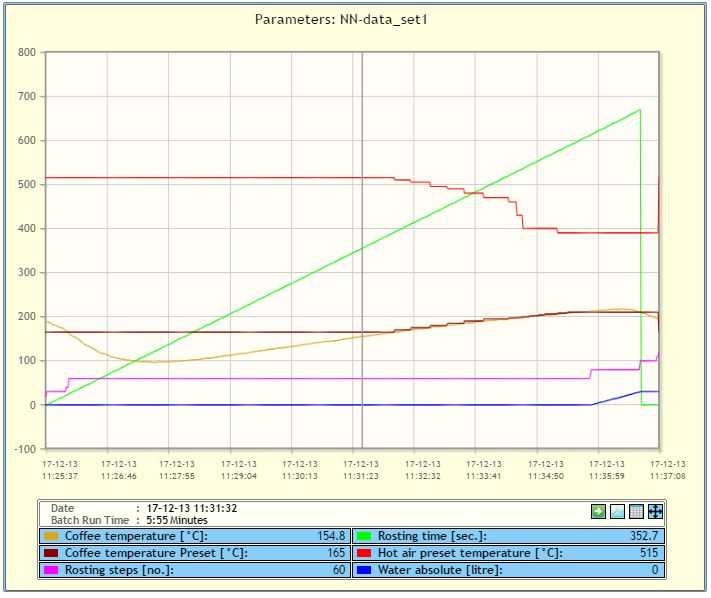

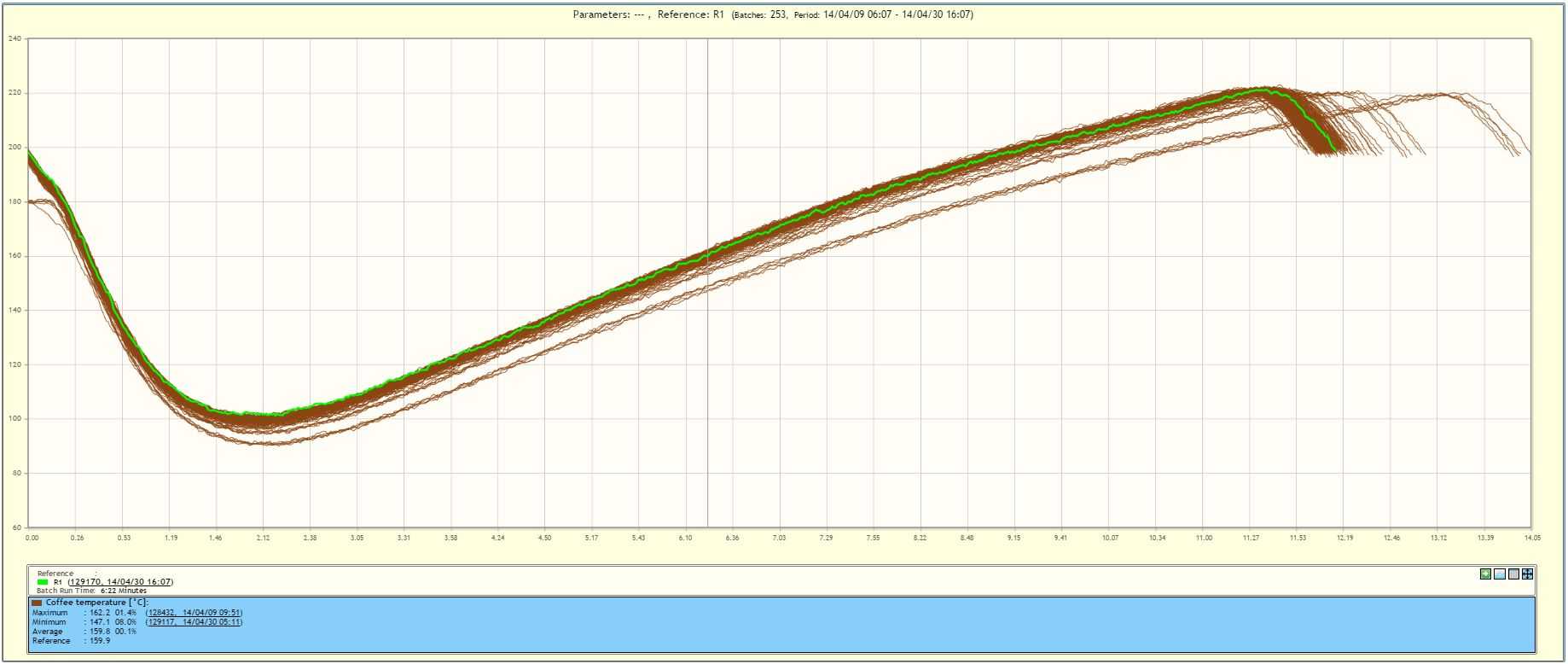

The advantage over pure archiving solutions: NN-QM specifically shows the phase in which the coffee is roasted. In particular, the procedural state of the roasting chamber is recorded and archived together with the roasting data (setpoint and actual values).

This increases the production reliability, because the corresponding parameters can be displayed with just one click to answer any questions about product quality. Thus, the programme is also an important component for any DIN / ISO 9000 audit and can facilitate the certification accordingly.

Exact batch representation and evaluation

NN-QM offers the roaster a batch-oriented data representation in the production process, which can record all the data available in new plants. The batches are selected via the period or the batch number. In addition, the operator can save any additional information such as recipe numbers or types of coffee and attach laboratory reports.

The roasting process is recorded consistently and transparently for sustainable analyses and the results are filed. The batch data can be output as a PDF, CSV or Excel file.

The software can be quickly and easily customised, for example, with regard to the access rights for employees, the amount and presentation form of the data collected or the customer-specific nomenclature.

A connection to various inter-faces such as SPS is possible; besides the detailed data can be exported or saved locally. For existing plants, the data representation depends on the available measuring instruments – but these can be retrofitted or optimised according to customer requirements.

The quality management system has proved to be successful in several large roasters in Europe; through continuous development and programming, it is constantly adapted to suit the requirements and desires of the customers.

Thus, NN-QM is another future-oriented component in the product range of Neuhaus Neotec for the entire field of coffee processing and refinement, which can be easily integrated into existing control systems for the RFB and drum roasters.

Graphic 1: The roasting data are stored batchwise and are recorded consistently and transparently for sustainable studies. (Source: Neuhaus Neotec)

Graphic 2: An overlay of the batch curves results in a comparison of the reference curve to selected actual values. (Source: Neuhaus Neotec)