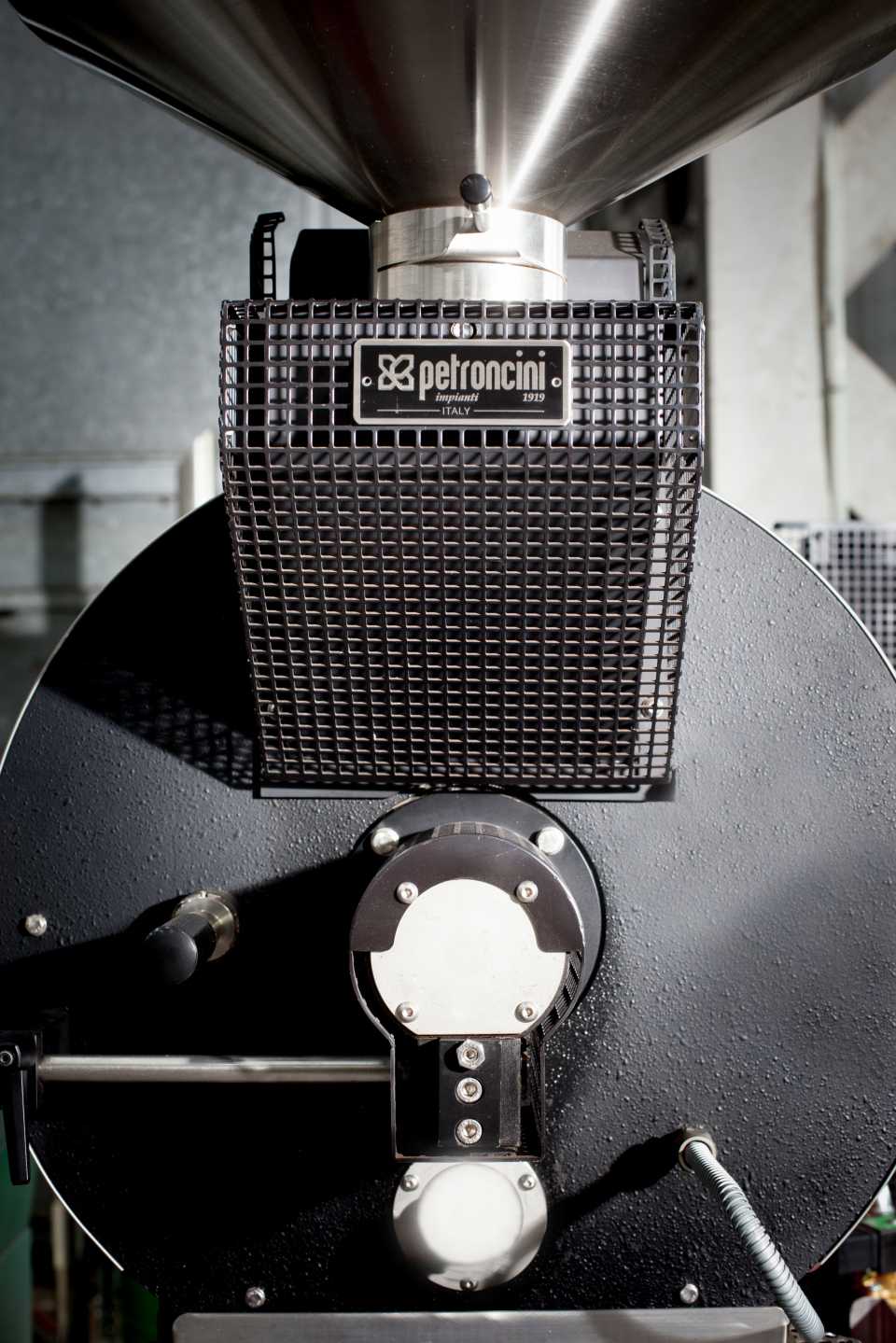

The knowledge and the wide experience in the world of coffee roasting have allowed Petroncini to design, manufactures and install complete roasting plants able to satisfy all customers’ needs.

For any coffee processing requires, Petroncini can provide the smartest roasting solution able to guarantee the best results in terms of consistency and replicability of aroma.

At the Host 2015 edition, Petroncini will present two model of roasters, each one studied for different types of production and different needs of plant installation.

The TMR400 will surely attract the attention for its wide size: with a more flexible configuration, the TMR modular roasters are specially designed for industrial goods that require high profitability and processing repeatability during the various phases of roasting processing.

Exceptionally for the HOST event, Petroncini will present the TMR400 in “transparency” modality: some details or components of the roaster, that are commonly closed and not visible from the outside, will be shared through special panels.

Petroncini is able to ensure the maximum efficiency of green coffee, even for small productions.

This is the second news that the company will present at HOST 2015: the SPECIALTY ROASTERS, the gems of the Petroncini production, designed to be particulary suitable for small handcraft production of high quality and gourmet market.

These roasters are equipped with all the properties and characteristics that are commonly associated to the roasters with greater capacity. For all purposes, TT5|10 and TT15|20 can be considered gems in terms of technology, strength of materials, design and creativity in determining the aroma.

Their production is about 40-60kg|h for the TT5|10 and 60-80kg|h for the TT15|20, depending on the desired level of roasting.

They are available in two types of configurations: STANDARD with a manual management of the roasting stages and a next-technology modulating burner that allows the operator to modulate the intensity of the flame through an easy-to-use power positioner; ROASTING PROFILE, that includes dedicated software for the roasting curves management with the ability to set profiles with two different configurations, with temperature priority or time priority.

For this reason, these models are particulary suitable also for high technology lab and R&D centres.

Petroncini Impianti will be present at the Hall 13 stand G16 G22 H15 H23, 23-27 October in HOST 2015.