Share your coffee stories with us by writing to info@comunicaffe.com.

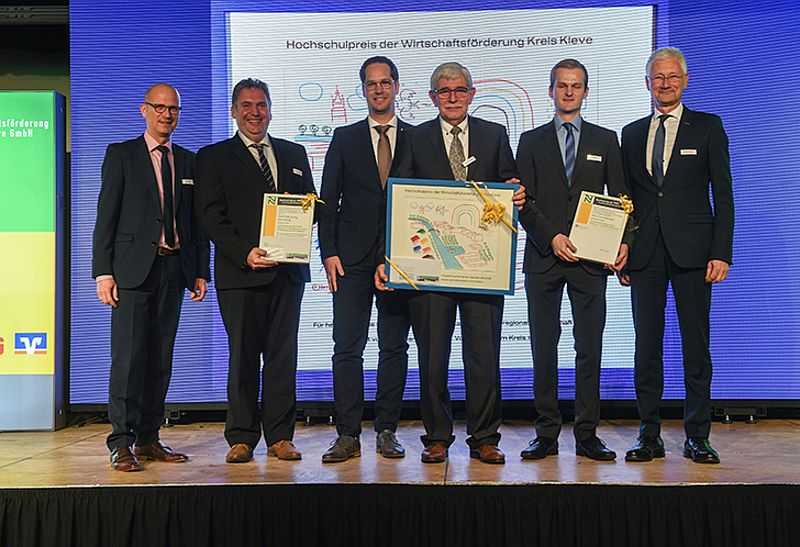

EMMERICH AM RHEIN, Germany – The German economic development agency Wirtschaftsförderung Kreis Kleve has recently awarded the university prize for the seventh time: Probat received the coveted award for improving quality control in the ongoing roasting process.

The prize is awarded to outstanding, innovative regional projects by the Rhein-Waal University of Applied Sciences. This time, Probat had also applied: Tim Ambrosius, dual student at Probat, pursued the challenge of implementing a smart colour sensor for real-time determination of the degree of roasting in a roaster controller, as part of his Bachelor’s thesis.

The successfully completed project convinced the seven-member jury and prevailed against a total of eleven competitors.

Sebastian Fichthorn, Head of Software Engineering & IT at Probat and Professor Dr. Ing. Dirk Nissing, Dean of the Faculty of Technology and Bionics at the Chair of Control Engineering at Rhein-Waal University of Applied Sciences, jointly supervised Tim Ambrosius’ work: “With this successful completion of the project, we have once again underlined our claim to market and technology leadership in the coffee industry.

Tim Ambrosius’ research results mark an important impulse for the way innovative solutions can be used to meet current challenges in the industry,” says Sebastian Fichthorn. „And the cooperation between industry and research is decisive for the future performance of the economy and society.“

About the project: Usually, coffee beans are roasted according to temperature and time. Once the roasting process is complete, a sample is taken to determine the colour value of the roasted coffee beans.

This colour value then determines, among other things, the quality of the end product. If the actual value deviates from a target value, the roasting profile for the next roasting is adjusted accordingly.

The smart colour sensor implemented by Tim Ambrosius in the roaster control system now enables colour value recognition in real-time, the so-called online-measurement. This considerably simplifies quality control and makes the roasting process more efficient.