Composed of over 1,800 chemical components, coffee is one of the most widely-consumed drinks in the world. The seeds (coffee beans) from the plant of the same name are roasted and ground, allowing a flow of hot water to extract their soluble content.

Undissolved solids are filtered from the dissolved particles, and the resulting liquid becomes the concoction that much of the population drinks every day.

Brewers have developed numerous techniques to prepare the popular beverage.

All techniques are based on leaching via a solid-liquid extraction, and each method aims to produce the best quality coffee possible – a subjective feat that, despite evaluations from professional coffee tasters, is often a matter of personal preference.

Because so many chemical compounds comprise a single batch of coffee, determining precise correlations between the solubles’ physical parameters and the beverage’s quality is difficult.

However, understanding the mathematics of extraction can help identify the influence of various parameters on the final product.

In a paper publishing next week in the SIAM Journal on Applied Mathematics, Kevin M. Moroney, William T. Lee, Stephen B.G. O’Brien, Freek Suijver, and Johan Marra present and analyze a new multiscale model of coffee extraction from a coffee bed.

While past studies have investigated the mathematics of coffee extraction, researchers have previously paid little attention to the drip filter brewing system.

Drip filter machines make up about 10 million of the 18+ million coffee machines sold yearly in Europe, and involve pouring hot water over a bed of coffee grounds housed in a filter. Gravity pulls the water through the filter, extracting coffee solubles from the grains during the flow.

Moroney et al.’s current paper focuses on drip filter machines and expands upon the authors’ previous work, which was published in Chemical Engineering Science in 2015.

“Most of the models of coffee extraction we found in the literature either focused on batch extraction in a well-mixed system, or derived general transport equations without proposing specific extraction mechanisms or validating with experiments,” Moroney said.

“In comparison, our model describes flow and extraction in a coffee bed, specifies extraction mechanisms in terms of the coffee grain properties, and compares the model’s performance with experiment.

Our initial focus on the flow-through cylindrical brewing chamber allowed us to consider the model in one spatial coordinate and ensure that the model assumption of a static bed was valid.”

The authors’ earlier paper presents the derivation of this general model, which considers bed dimensions, flow rates, grind size distribution, and pressure drop.

They assume isothermal conditions (constant temperature), because optimal brewing circumstances require a narrow temperature range of 91-94 degrees Celsius.

They also assume that coffee bed properties remain homogeneous in any cross section and that water saturates all pores in the coffee bed, eliminating the need to model unsaturated flow.

A set of conservation equations on the bed scale monitor the transport of coffee and liquid throughout the coffee bed.

Now the authors take that model one step further. “The model of coffee brewing published in Chemical Engineering Science was mathematically complete, but I would describe it as a model only a computer could love: a complicated system of coupled partial differential equations that can only be solved numerically,” Lee said.

“This new paper analyses that model to produce a reduced system of equations for which approximate analytic solutions can be found.”

Because coffee brewing involves so many components, simplifying the model becomes necessary. “In modelling a complicated physical process such as coffee brewing, one attempts to write down a system of equations which captures the essence of the process,” O’Brien said.

“In doing so, we initially make some simplifications, which neglect some aspects of the real problem. For example, real coffee contains a large number of dissolved substances; we simplify our model by considering the case of a single such substance. The mathematical model then comprises conservation laws (mass momentum), which in their complete form cannot be solved exactly.”

The authors then utilize non-dimensionalism, which measures variables with respect to fundamental constants intrinsic to the problem, to further simplify the extraction model.

This technique reduces the number of parameters–which include brew ratio, brewing time, water quality and temperature, grind size and distribution, and extraction uniformity–therefore letting the authors recognize the equations’ dominant terms before they begin actively seeking solutions.

“Neglecting smaller terms thus allows us to find approximate solutions,” O’Brien said.

Recognizing these approximate solutions helps the authors easily identify typical trends. “Approximate solutions are formed based on the dominant processes in the coffee bed during different stages of the extraction process,” Moroney said.

“Initially, the concentration of coffee in the bed is determined by the balance between a rapid extraction from the surfaces of coffee grains and the rate at which coffee is removed from the coffee bed by the extracting water. Later in the process, the extraction is dominated by slow diffusion of coffee from the kernels of larger grains, which was initially negligible.”

Although the timescales of the aforementioned extraction methods are much shorter in fine coffee grinds rather than coarse grinds, the authors can still construct approximate solutions because of the timescale ratios’ small size.

“The value of the solutions lies in the ability to explicitly relate the performance of a brewing system with the properties of the coffee, water and equipment used,” Moroney said. These solutions help predict the coffee quality for specific brewing configurations.

In the end, the authors intend for their model analysis to expose the mathematics involved in coffee brewing. “The research work is ultimately aimed at improving our understanding of the brewing process and understanding the relation between brewing process parameters and perceived coffee taste,” Marra said.

A possible next step involves incorporating the changing coffee bed shape that occurs while water flows through the conical filter holder of a drip filter machine.

“This causes both the extraction and the flow rate through the coffee bed to become a function of position,” Marra said. The authors’ research also has the potential to inspire further models on different extraction processes, including unsaturated flow and the trapping of air pockets in a coffee bed, in the never-ending quest for a perfect cup of coffee.

###

Source article: Asymptotic Analysis of the Dominant Mechanisms in the Coffee Extraction Process. SIAM Journal on Applied Mathematics.

About the authors

Kevin M. Moroney is a Ph.D. researcher with the Mathematics Applications Consortium for Science and Industry (MACSI) in the Department of Mathematics and Statistics at the University of Limerick. William T. Lee is a lecturer in the Department of Mathematics and Statistics at the University of Limerick, and is a part of MACSI.

Stephen B.G. O’Brien is director of MACSI and a professor of applied mathematics at the University of Limerick. Freek Suijver is a program manager and senior director of the Program Management Team at Philips Research Laboratories. Johan Marra is a principal scientist and chemical engineer at Philips Research Laboratories.

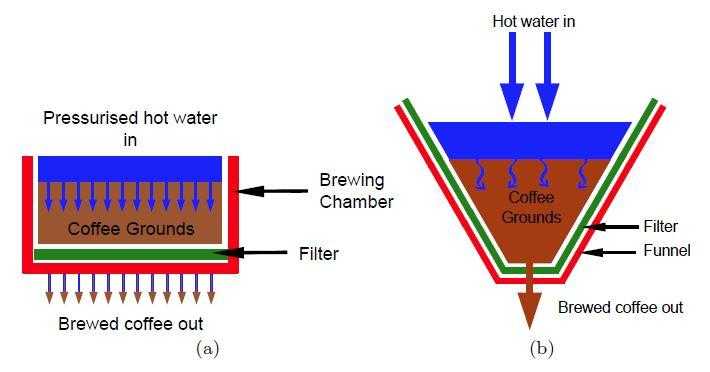

In the picture above: (a) Espresso coffee is made by forcing hot water under high pressure through a compacted bed of finely ground coffee. (b) Drip filter brewing involves pouring hot water over a loose bed of coarser coffee in a filter. In either method water flows through the bed, leaching soluble coffee components from the grains. Any undissolved solids in the fluid are filtered from the extract as the liquid leaves the filter.

Credit

Image credit: Kevin M. Moroney