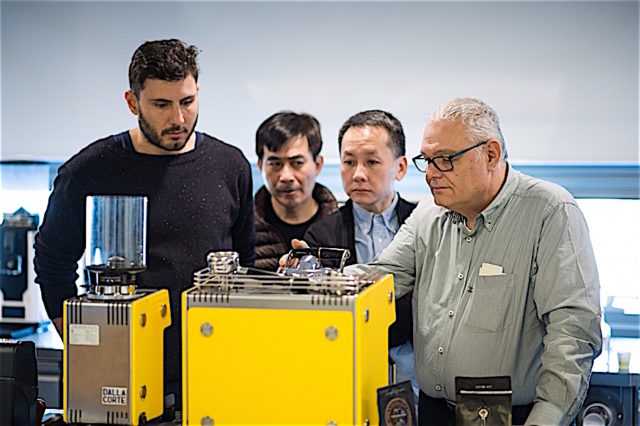

MILANO – Dalla Corte is a leading Italian company that specialises in the manufacturing of professional coffee machines manufacturing. Paolo Dalla Corte (in the PICTURE with his daughter Valentina), the company’s co-owner together with his sister Elsa, tells this success story in an exclusive interview for Comunicaffe International.

Could you share a brief history of Dalla Corte with us?

Dalla Corte was established in 2001, but our origins date back to 1947, when my father Bruno Dalla Corte began working at La Cimbali. In the 1960s, my father contributed to the creation of the first ever-machine with a constant pressure extraction process, the E61.

He then invented the steam circulation technology with which La Spaziale started its business as an espresso coffee machine maker.

My father and I worked there for many years. In 2001 our desire to innovate prompted us to start a new enterprise.

Together with my sister Elsa, we founded Dalla Corte, a family-owned company which put the first independent multi-boiler espresso machine on the market. Since then the innovations have really been numerous.

What does it mean for Dalla Corte to be a point of reference in the sector? What is the added value of such a label?

Being a point of reference as a quality manufacturer is a great responsibility; the espresso machines and coffee grinders we design and manufacture must always go beyond the raw material used. Understanding the needs of those who use our machines and evaluating what an espresso must deliver have always been our primary goals.

Our brand also brings with it the added value resulting from solid research and innovation, even through the development of ideas in synergy with our partners, such as “Coffee and Talks”, the world tour that in 2017 led us to hold events all over the world, according to the principle of “live, learn, share”.

What are the new challenges imposed by the market of traditional coffee machines and what are the prospects?

The market does not impose anything but, through a series of signals, it calls for continued technological innovation in order to improve the extraction process and simplify the barista’s work. There are also signals reflecting the current trends or deriving from different cultures: we are more sensitive to signals from different cultures than from trends, since the latter, in many cases, fade out on their own.

In line with this view, two years ago we launched the Mina espresso machine, which allows the water flow to the coffee cake to be adjusted at each stage of the extraction process, maximizing the coffee aromas. At Host 2017 we presented the dc pro XT, which offers unprecedented precision and thermal stability.

Our efforts are definitely geared towards an advanced barista with a high degree of knowledge of the raw material. However, the market is not only comprised of these people. For this reason, we have chosen to offer solutions for a market with a different level of training and/or knowledge offering a machine connected to the on-demand coffee grinder (GCS), an electronic grinding control system that allows less experienced baristas to always maintain the desired level of quality.

With regard to the prospects for the future of espresso coffee, I can certainly say that the market of coffee and dedicated machines will be increasingly divided into two segments: a gourmet segment and a larger “mass market” segment.

Based on the philosophy that drives our choices, we will continue to seek the best in terms of quality, being confident that the gourmet segment is, in any case, growing globally.

As a result, we will gradually move away from the mass market segment, where I see chaos among capsules, low-cost coffee, and various alternative solutions intended only to increase figures while standardizing and lowering quality.

Can you give us some economic data on your business?

I think a company’s performance is measured based on the achievement of the established goals, not just in terms of revenue. However, I can say that currently 2017 is seeing a 13% increase over 2016. The Italian market has grown compared to last year and is now about 10% of our sales, a sign of the greater visibility of our brand and a growing focus on quality products. In 2017 we have strengthened our sales team and this has allowed us to consolidate important markets for us such as Germany, South Korea, Switzerland, Japan, and Australia, and to enter the American market thanks to a recently signed partnership with Alpha Dominche, the producers of Steampunk.

How do you see the challenge in the Italian market and in the world?

Attention to highly technological espresso coffee machines is growing above all internationally. Attention is also increasing in Italy although the overall speed toward a high-end segment is rather slow. In Italy, in my opinion, there is little awareness of the beneficial effects that greater promotion of quality raw materials would bring to the entire supply chain. However, positive changes are being noted, especially among small business owners and those operators who have traveled to countries where there is a greater focus.

Nevertheless, it is always right to emphasize that Italy is the first manufacturer of espresso machines and a point of reference internationally.

Dalla Corte has a unique espresso machine, Mina. What is its story?

Mina was developed to meet a specific need of professional baristas.

In fact, the number of baristas wanting to configure the machine and personalize the extraction is growing every day, together with the desire for unique aesthetics.

For these reasons, we introduced a controlled variable in Mina: the water flow of the dispensing unit. This design was related to the fact that the first phase, commonly called pre-infusion, is an important and delicate step. In fact, it is precisely in this stage that most of the aromas that will be found in the cup are developed.

The ability to modulate, with maximum precision, the flow of water that comes into contact with the coffee cake starting from zero bar and increasing at a rate of up to 11 grams per second (the maximum quantity delivered in the absence of coffee in the filter) adjusts the impact of the ground coffee with water and enhances the extraction conditions.

In addition, the 5-step adjustment with a half-a-gram per second rate of precision allows the barista to obtain various extraction flow curves based on the coffee itself and the desired result. To achieve this, we invented DFR – Digital Flow Regulation. This proprietary patented technology allows the flow of water to be managed with the utmost precision. The single group Mina espresso machine came from this idea. The aesthetics are unique (we were among the companies awarded with the SMART Label at Host 2017) and customizable with any material and decor. But Mina enables baristas to go even further. For example it offers the opportunity to create multiple coffee points in the same café, thanks to the SMART BAR solution. All this allows flexibility that cannot be achieved with a traditional multi-group machine.

Finally, what was your take on Host 2017? Your own machines aside, what was the most interesting machine? Innovation was the star of Host…

This edition of Host once again proved to be the most important event in the world in our industry; it is a trade fair on which companies focus their attention and efforts to offer something new to the market.

With regard to machines, a number of them were presented, often still in progress, because designing a new model is always a long and complex operation.

More than by a specific machine, I was struck by the growing number of companies trying to make equipment to be offered on the global marketplace, with significant investments in aesthetics, although in my opinion not always with significant technological and functional content.

At the same time, however, I am pleased to see more attention being given to the coffee grinder, until recently ignored by many, and which is now becoming increasingly important: in fact, it is a key element, since an espresso is indeed the result of a complex process. I am certain that with time the market will realize what products are “real” novelties compared to those which are such only on the surface, with no substance underneath.

Nonetheless, I remain positive for the future: we still work to “Make It Better“.